I Took Apart The Top End

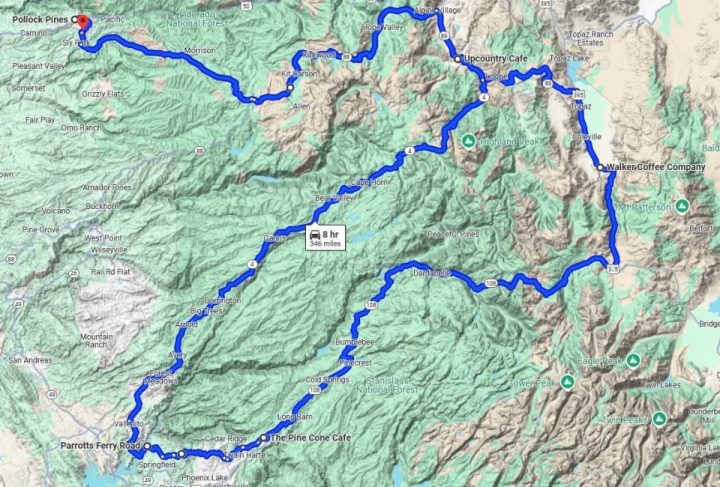

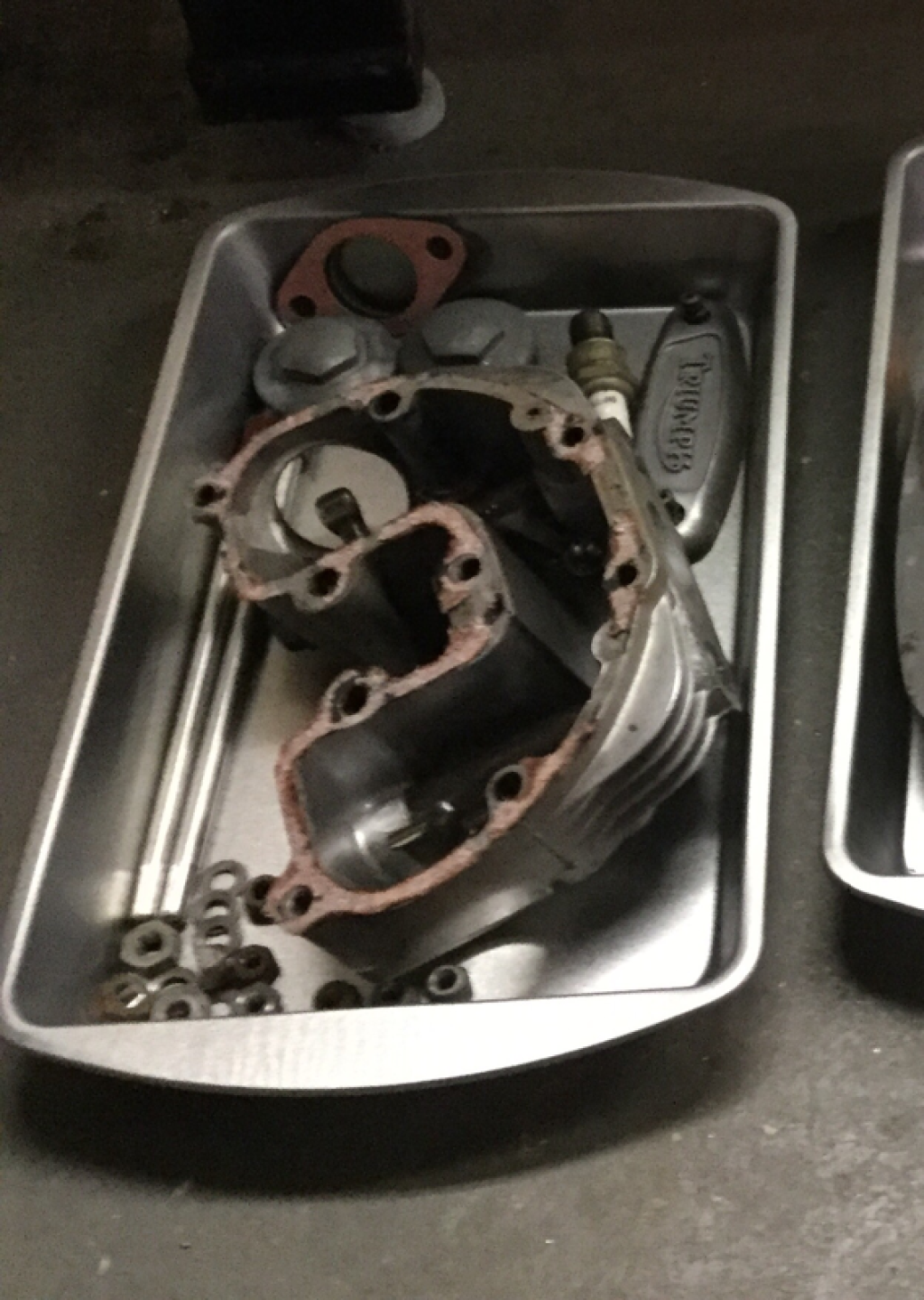

The Rocker Box had to come off first. We figured out that most of the bike uses Whitworth which is a British standard hardware. This is no longer used but since my bike was from 1970 they still used this system to build the bike. The nuts to hold the head down were 9/16 which is imperial not Whitworth. This leads me to believe that somewhere down the line a previous owner had to replace the nuts. The exhaust rod was connected on the inside as the intake rod was located on the outside of the tunnel leading through the head. The pictures below are pictures of the process of taking off the rocker box and the parts we ended up with at the end.

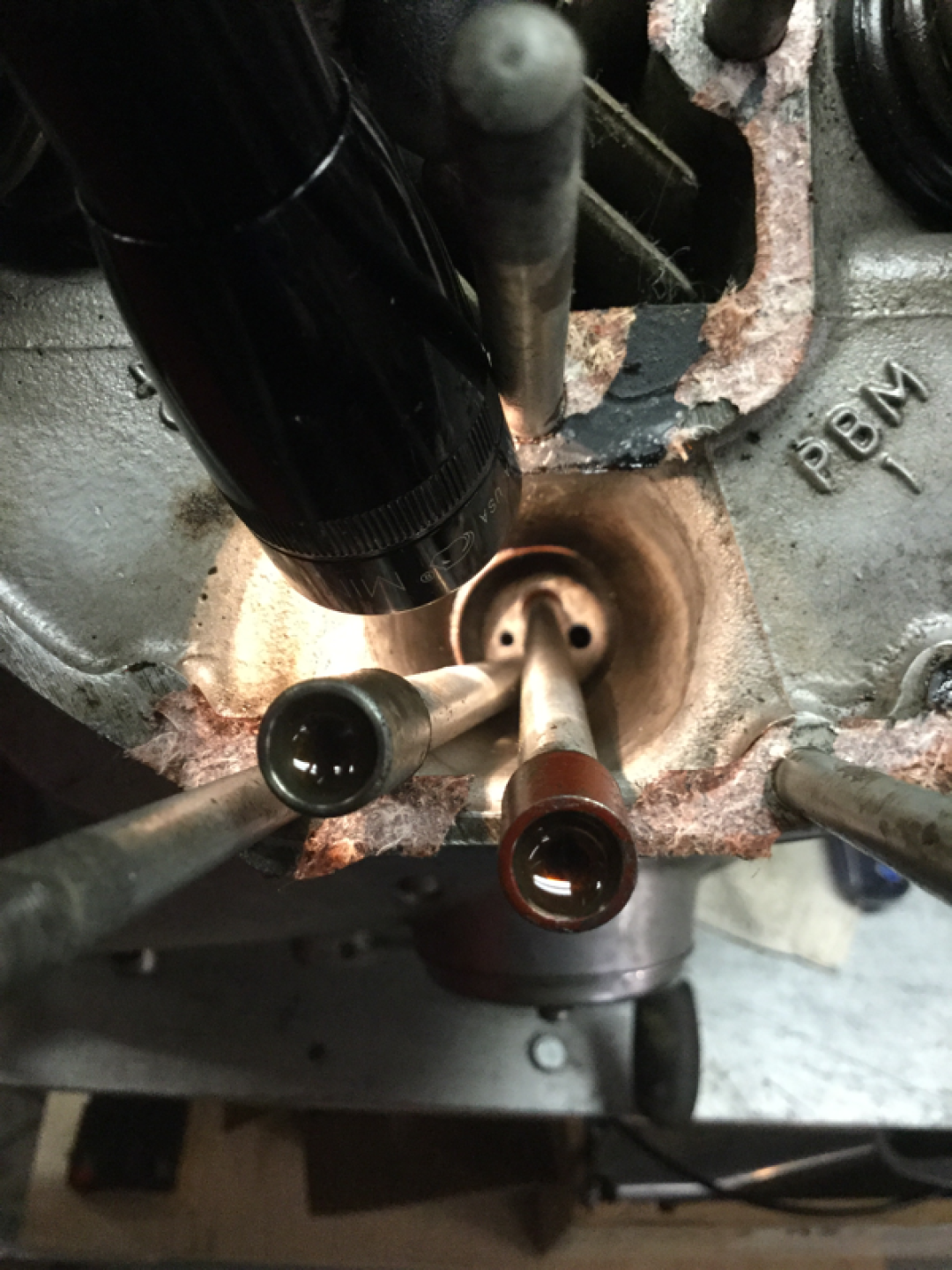

The Head came off after the Rocker Box. The Head was in pretty good shape and it still had its copper gasket. The copper gasket was not propperly doing its job because it had not been annealed before being put between the head and the cylinder. The annealing process helps the gasket to become 'butter soft' and pliable enough to fill in the gaps and create a tight seal between the head and the cylinder. The pictures below are pictures of the process of taking off the head and the parts we ended up with at the end.

The last thing that I did today was take off the cylinder. The paper gasket was torn to shreds so we will have to replace it like we have to do with the rest of the original paper gaskets. When we removed the cylinder we found that when the piston was moving up and down through the cylinder it wore down the cylinder to the point that now the piston is too small for the cylinder. It is possible to find a piston that is slightly bigger so that it fills in the space made by the ware that was made by the motion of the piston. We will have to find one of these slightly bigger pistons to replace our original piston. Other than that we have a complete top end of the motor disassembled. The pictures below are pictures of the process of taking off the cylinder and the parts we ended up with at the end.

Follow

1K

Follow

1K