How riding jeans are made

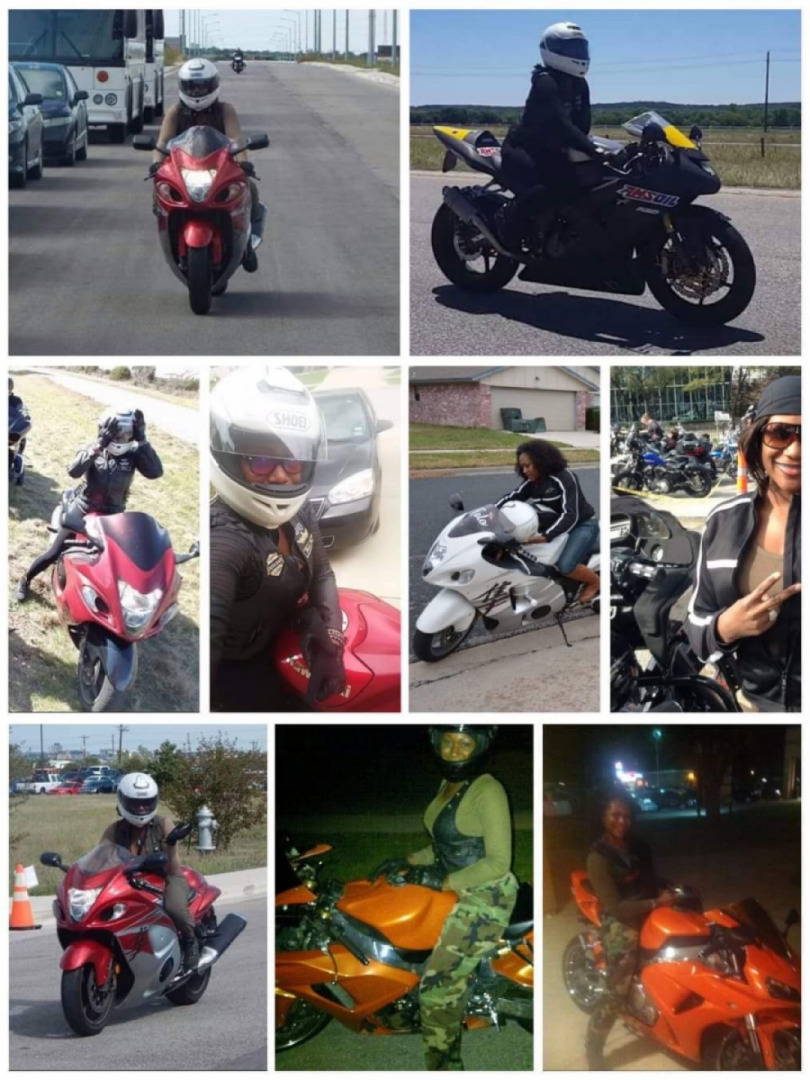

Many riders wear them as an alternative to leathers – but have you ever considered what goes into manufacturing a pair of riding jeans?

Although originally produced as a hard-wearing item of clothing, denim jeans have become somewhat of a popular fashion icon over the years. So it comes as no surprise that this versatile material eventually found its way into the manufacture of riding jeans. Of course, no safety conscious person should consider riding their bike in just a pair of fashion jeans, and this is where owning a good pair of protective riding jeans come into the equation. I took a trip to Norfolk to find out how they are made.

Hood Jeans are somewhat of a rarity in the manufacturing world, as their products are made here in the UK. The companies’ roots stretch way back to 1955 (meaning that this year, they’re celebrating 60 years of manufacturing history). Most of their production is currently done at a factory in Leicester, but their headquarters are in Norfolk – which is where I met owners Chris and Julie Easterford to find out what processes go into producing a pair of riding jeans.

It should be pointed out here that not all manufacturers use the same work methods. Hood employ a certain amount of hand-production in the production their products, whereas many other manufacturers processes are automated nowadays. Something else worth mentioning is that there’s a variety of para-aramid Kevlar-type protection products on the market with slightly varying working properties and different manufacturers often have their own fancy name for them. Hood currently uses a K-Tech para-aramid material, so for the purposes of this article I’m just sticking to referring to the material as ‘para-aramid’. The type of armour that can be fitted to riding jeans can also vary (the images here show D3O armour). As to the stitching the materials together – I’m not even going to attempt to tell you about all the different variations involved (cross-stitch, lock stitch, plain stitch, etc, etc).

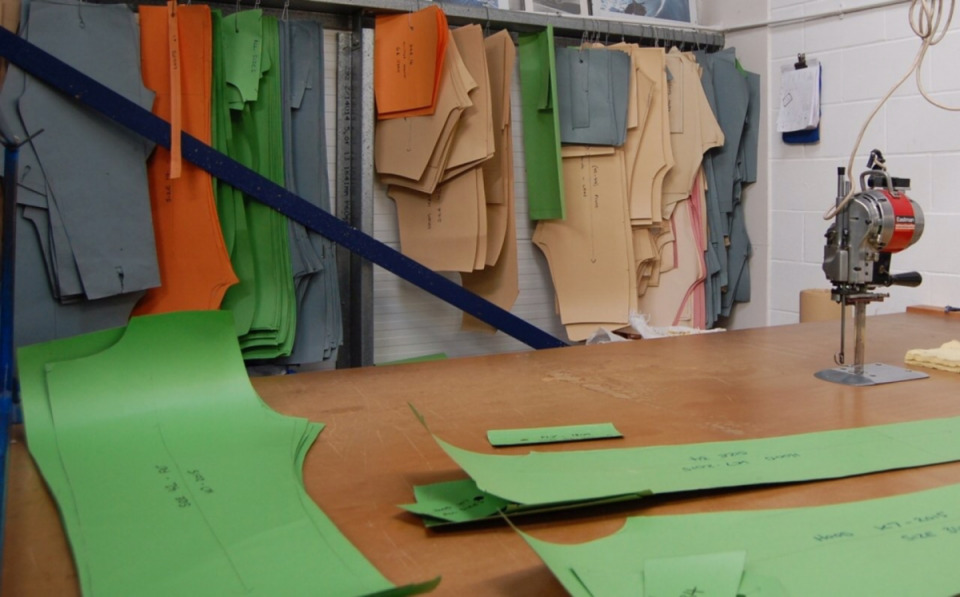

How protective jeans are produced

The process starts with a design pattern (normally consisting of two main leg panels, plus the pockets, waist band and other ancillaries). These are arranged on the outer denim to get the least waste possible out of the cutting. (Picture: Michael Barraclough).

Here, the para-aramid inner protective lining is being cut to shape in several layers several layers at a time. Because of the nature of the material, cutting blades can be blunted very quickly.

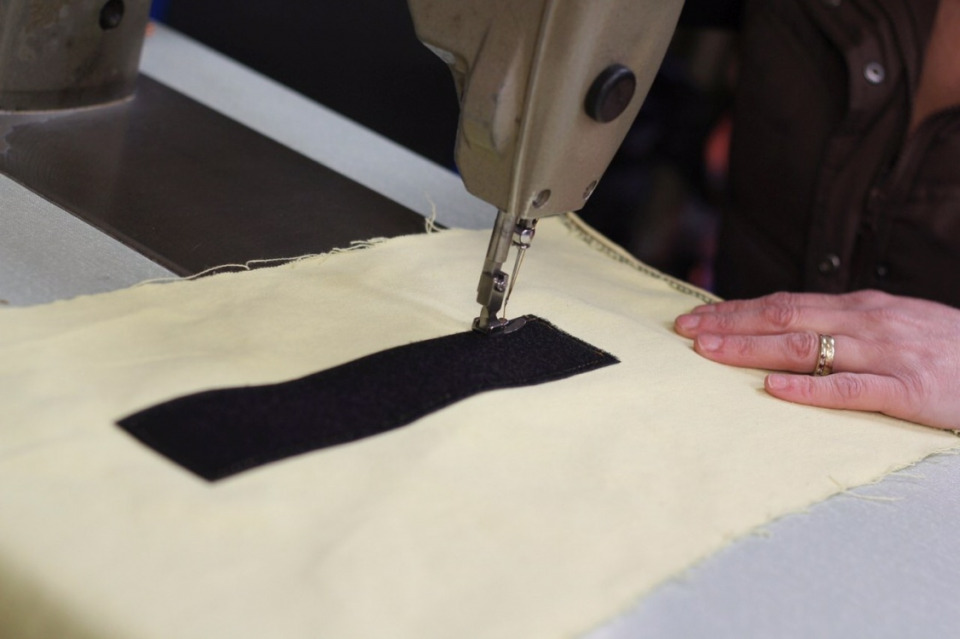

Positional red dots are then marked (hidden in this picture) so that a Velcro fastening for the armoured protection can be added. Some manufacturers use fixed position armour pockets, but the advantage of a Velcro fastening is that the armour can be moved to suit individual stature.

Sewing any Para-aramid is hard work (so imagine how hard it is for the emergency services to cut it off in an accident – so don’t have one)! Paradoxically using a thicker lining is normally cheaper (it tends to be more loosely wound); the trade-off is that the protection qualities can suffer.

The stitching of the denim outer commences using a cord made from a mixture of thread and nylon, but to stitch-in the inner protective lining, a para-aramid thread is used.

The outer pockets straight off the cutter could be mistaken for a line of bunting. Here they are being hemmed and a pattern added.

A safety stitch is added to help protect the seams.

Rivets are inserted where needed. Every effort is made to avoid riveting through the tough para-aramid material if possible.

Mounted to the front trouser pocket, you’ll find that little coin pocket that you can never get your finger in…

A clever machine cuts and stitches a hole for the fly stud to go through.

The front and back half of the jeans being stitched together.

The first time the para-aramid and denim material meet is when the fly zip is stitched on.

The inner lining is now ready to be stitched into position (note that the waistband has not been added at this stage).

The label for the washing instructions is stitched inside.

A clever little attachment folds the waistband material as it is stitched to the rest of the trousers.

The brand label is added.

The belt loops complete the production – almost.

Stitching the bottom of the legs is normally left till last; then if a customer requests a specific leg length requirement, it can be adjusted at this final stage.

Who are Hood Jeans?

Based in Attleborough, Norfolk, Hood Jeans is a small, family-run company originally set-up by Chris and Julie Easterford in 1998 – but the roots of companies’ roots go back a lot further.

To this day, Hood Jeans remains a family run company with Chris and Julie enjoying the personal touch that this allows them to give their customers. Chris says: “Our customers have given us so much support and encouragement; it’s this backing that’s made us the company we are today”.

Follow

2.9K

Follow

2.9K