Moto Guzzi – “Born out of the wind tunnel”

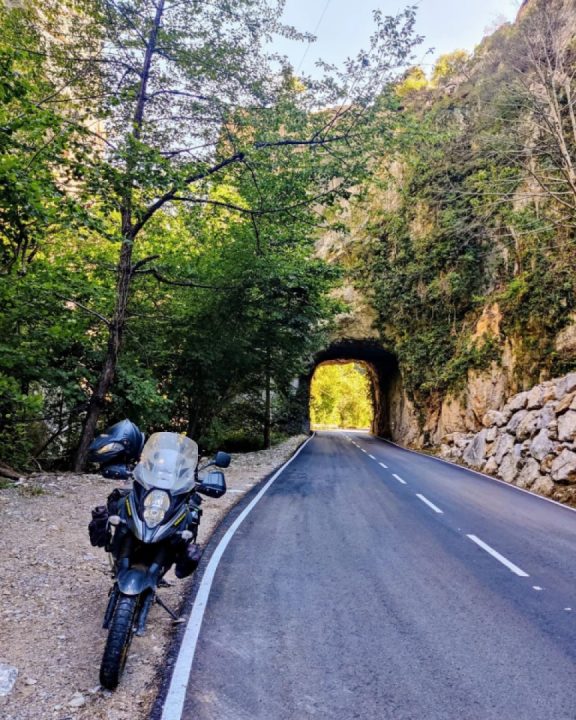

Tucked away in the corner of a town called Mandello del Lario near Lake Como’s shore sits the factory of iconic Italian motorcycle manufacturer, Moto Guzzi. 2021 marks Moto Guzzi’s 100-year anniversary; it’s the oldest European manufacturer in continuous motorcycle production. Within the factory complex is one of the first-ever production motorcycle wind tunnels – an installation fashioned by the racing spirit of Moto Guzzi’s founder, Carlo Guzzi.

Carlo Guzzi understood that with the increasing performance of racing motorcycles, chasing performance improvements would not only be the search for more power but to use power more efficiently. He knew that fighting against the engine’s power driving the motorcycle forward is the air’s pressure slowing the motorcycle down – causing drag – and that drag causes turbulence, reduces maximum speed, makes the vehicle unstable, increases wind noise and discomfort, and reduces its fuel economy.

He surmised that if the motorcycle’s shape and rider’s position was optimised in the airflow, significant performance gains could be achieved – these as applicable to a race bike as they are to a road bike and indeed a bicycle, F1 car or supersonic aircraft.

Guzzi drew up initial concepts for a wind tunnel in 1950 working with his older brother, Giuseppe, “Naco”. Naco had graduated as a Civil Engineer and designed many of the Moto Guzzi factory buildings and its hydro-electric power plant. Completed and inaugurated in 1954 was the world’s first motorcycle-dedicated wind tunnel.

Guzzi’s wind tunnel is an Eiffel-type design located behind the Moto Guzzi factory. The Eiffel-type wind tunnel consists of a long straight tube that brings fresh air in at one end and exhausts it at the other. The design benefits from it’s long and narrow construction, taking up less real estate than other wind tunnel designs, and making it relatively cheap to construct and operate.

Despite its low airspeed potential of this design and issues with external environmental influences, such as changing atmospheric and temperature conditions, the tunnel provided Moto Guzzi with a way of improving the aerodynamics of their machines.

A honeycomb flow-conditioning screen positioned ahead of the test object ensured a smooth, laminar flow of fresh air was pulled-in from outside the through the 8.2 m (26.9 ft) diameter inlet contraction. The total length of the wind tunnel was 28.5 m (93.5 ft).

The air was drawn in over the test object at speeds up to 225 kph (140 mph) by a fan powered by a military-surplus, 900 bhp FIAT V12 aircraft engine powered. A 310 hp electric motor later replaced the FIAT V12. With variable motor speed and fan blade pitch (on the three blades), it was more economical and efficient, more controllable and created lower noise levels.

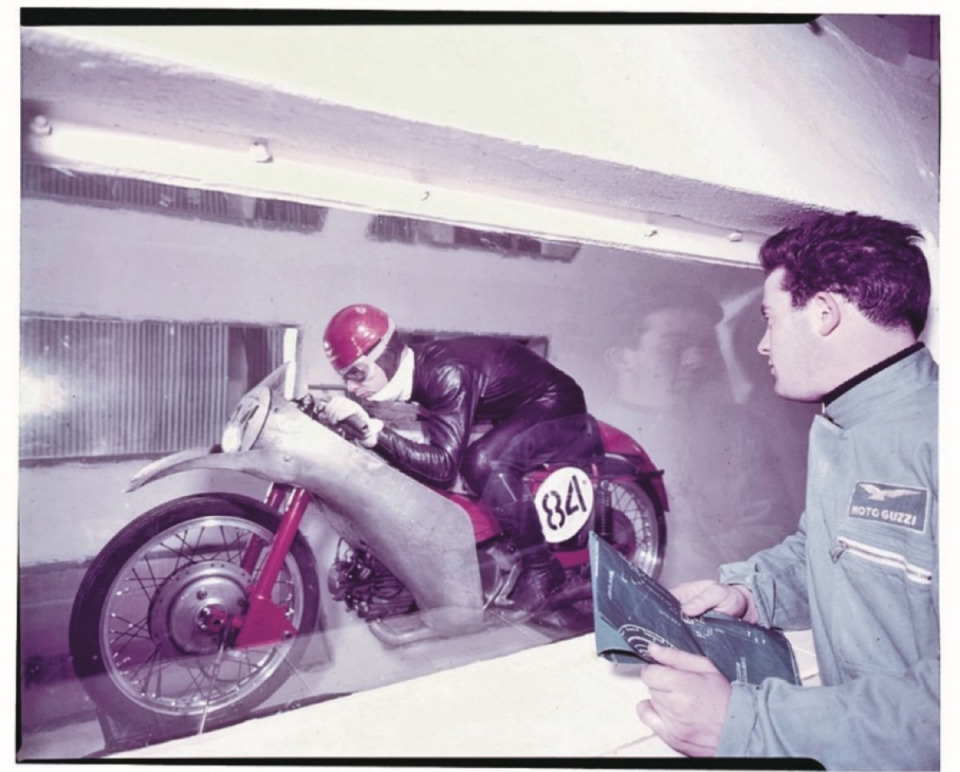

Moto Guzzi engineers would mount a motorcycle and rider (the test object) on a balance frame/pedestal free to move longitudinally (with some oil-damping) during aerodynamic testing. This mounted in the 2.6 m (8.5 ft) tall test section of the wind tunnel.

As the air hit the front of the motorcycle and rider, the balance was deflected – like a swing-boat in a fairground – proportionally to the test object’s aerodynamic profile. This deflection and wind speed were measured and displayed on an illuminated board called the Scala Convenzionale, similar to a giant tachometer. The rider could see the relative effects of his riding position and could change position accordingly. Aerodynamicists would work to develop and change parts of the bodywork to see how they affected the drag performance.

Forward-facing L-shaped pitot tubes mounted in the wall of the wind tunnel measured the wind speed. Each measures air pressure and corrects for changing barometric and static pressure measured at its static port where there is no airflow pressure effect. The pressures were measured on liquid manometers. Temperature and time were recorded in an adjacent control room by the wind tunnel operator, who would also control the wind speed and ensure its safe operation.

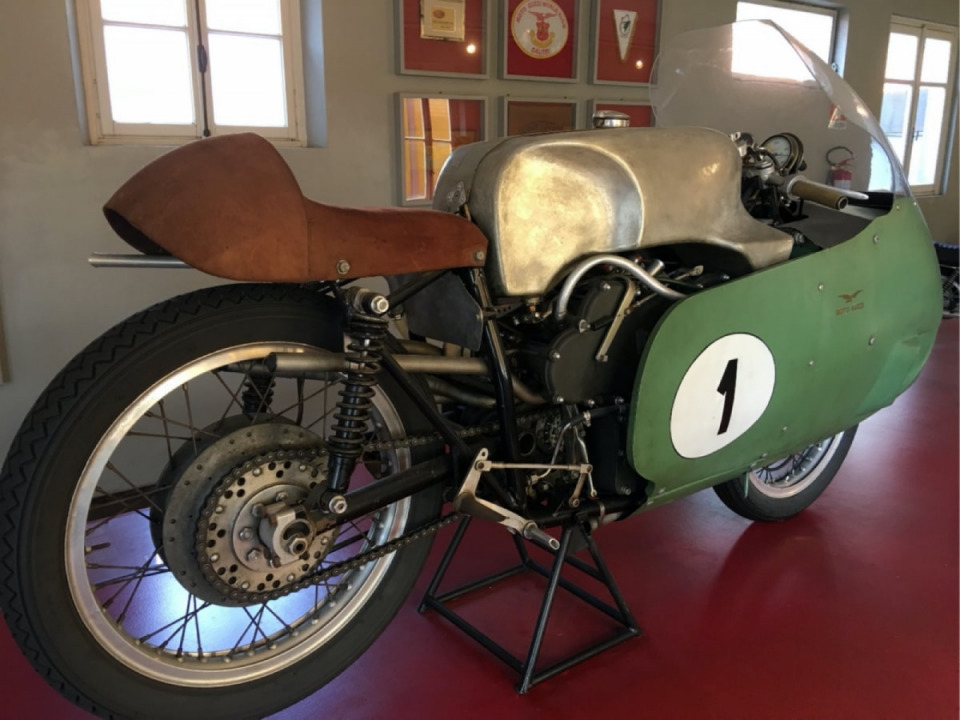

Moto Guzzi engineers first used the wind tunnel at Mandello Del Lario for testing racing motorcycles, and it’s understood that Fergus Anderson was the first rider to use it. With innovations such as the 500cc V8 racer’s dustbin fairings, racing and road motorcycles were developed and honed here.

The facility continued to be used sporadically into the 1980s when its development engineers tested the Le Mans Series bike there. It was heavily promoted for its aerodynamic prowess, as seen in the marketing photos and the sales brochures.

The 2005 Norge 1200 model was also said to be thoroughly tested in the Mandello Wind Tunnel. Generally, more modern Moto Guzzi aero experimentation has utilised specialist external facilities. It is common today, where huge investment in building new wind tunnels is hard to justify, especially for the smaller car and motorcycle manufacturers.

What was started by the beautiful, iconic Moto Guzzi wind tunnel, and it’s highly respected, innovative engineers will continue to impact future motorcycles for generations to come.

Thank you for reading this!

Credit: @Racecar Engineering, @Iain Gordon, @Piaggio & C. SpA, @F.Cornali

Follow

8.3K

Follow

8.3K