Rear Whell Bearings & Speedo Drive

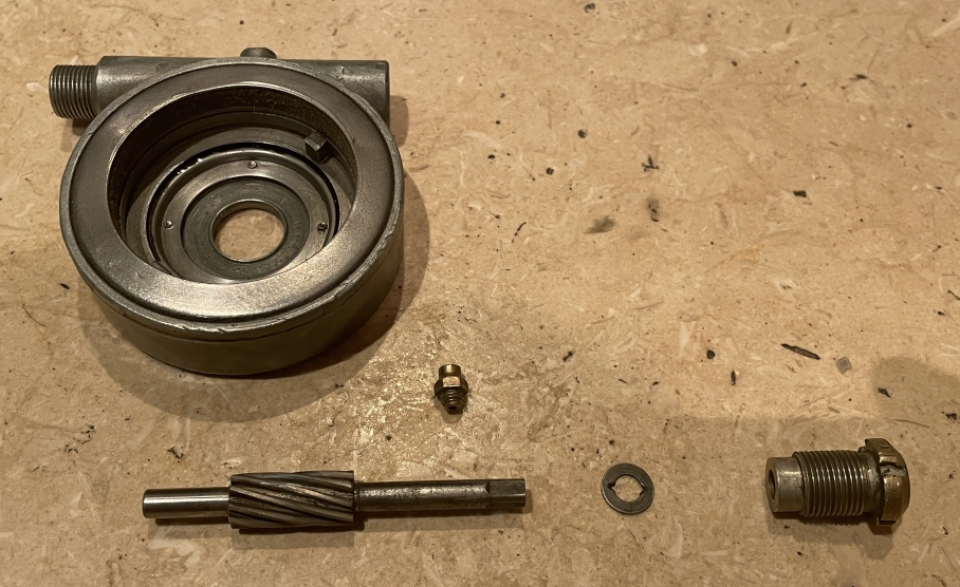

Once the bearing security cover has been removed the spindle can be tapped out using a hammer and drift, this also removes the bearing on the other side. The speedo drive can them be gently tapped off. Both were in good condition, the spindle just required a wipe to look as good as new. I took the speedo drive apart because I wanted to know what was inside it. All that is required is to unscrew the brass nut on the end.

All parts were cleaned and reassembled, I then refilled it with grease via the grease nipple. This forced the old black grease out from under the lip in the centre, when it all ran clean I stopped. The bearing locking cover washer that sits under the same bearing and the spacer that lives inside the speedo drive were also all cleaned.

The non speedo side bearing was greased and tapped into place using the spindle, the spacer was placed to check speedo fitment, all was OK so I started on the other side. Firstly the washer is placed in followed by the spindle, lots of grease followed by the bearing which was knocked in using a drift.

Follow

1.3K

Follow

1.3K