Tank & Fender Paint Pt. 2

The tank was a little different. It had a few little dents, probably mostly from road debris, but since there is no access to the inside, they had to be filled.

Because I want the option to not install the chrome trim strip that covers the welded seam on the top of the tank, I tried to fill in some of the irregularities in the seam. I used solder since it would be stronger than bondo.

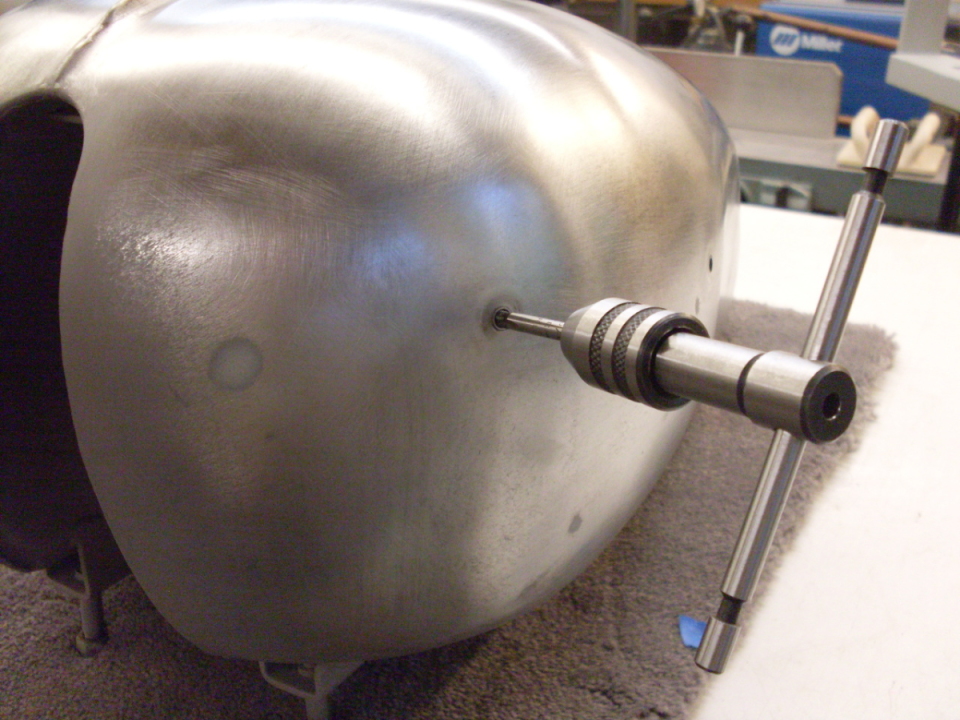

I chased out the badge mounting holes with a 2BA tap. They had a lot of crud in them from the paint stripper. To keep the new paint out of the threads, I plugged the holes with little set screws. No, I didn't track down 2 BA set screws. I used common 10-32, which is almost exactly the same diameter, but the thread pitch is very slightly coarser. I trimmed the set screws very short--maybe a strong 1/8"--so they got just below the tank surface before the threads bound up.

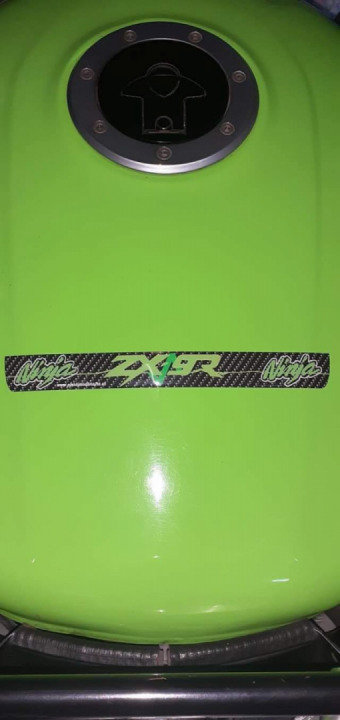

Then to plug the orifaces. The bung is filled with a standard BSP plug with the square head cut off and a straight slot sawed into it. I didn't want to paint inside the filler neck, so I masked down to the ramps where the cap grabs.

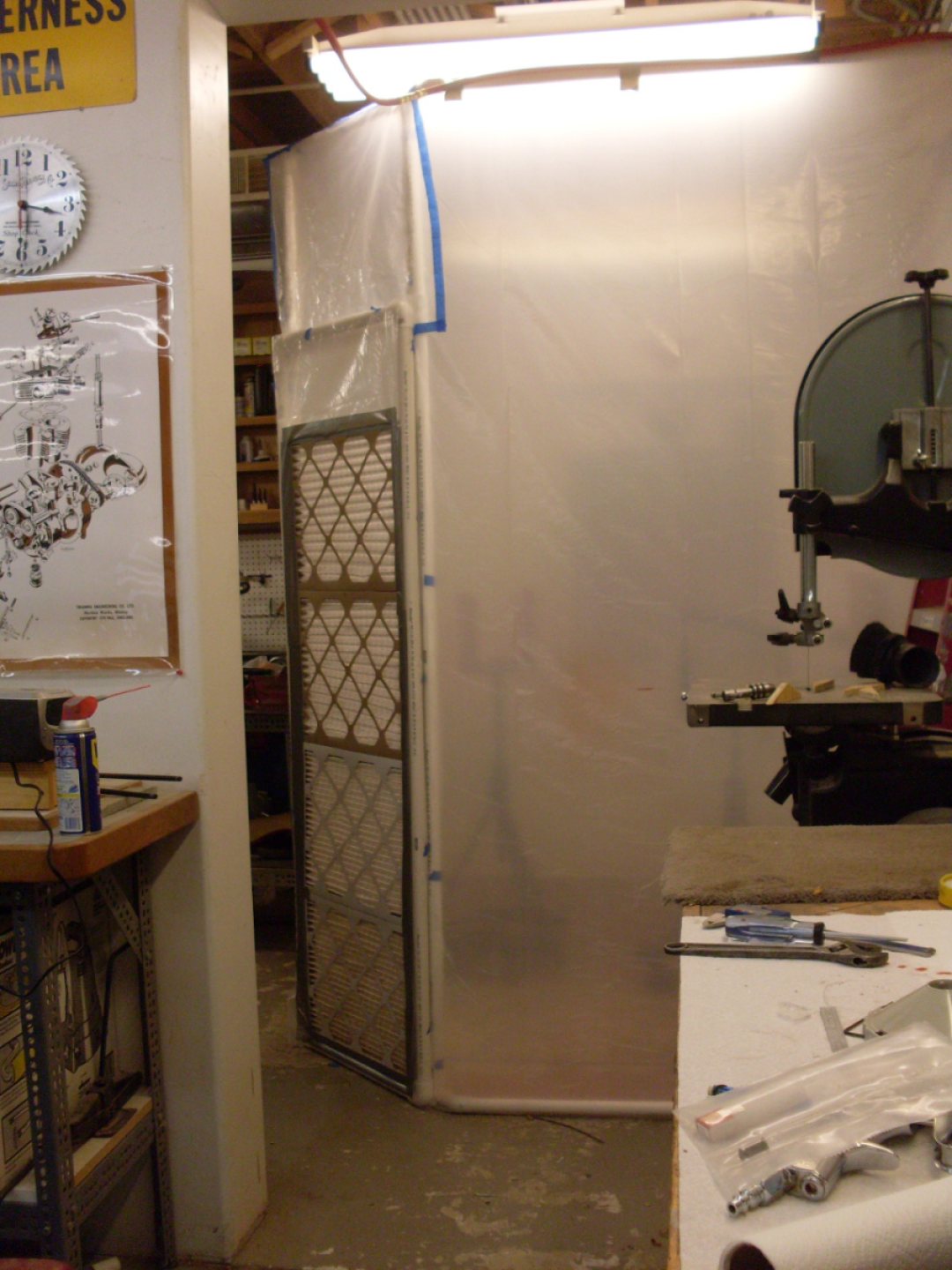

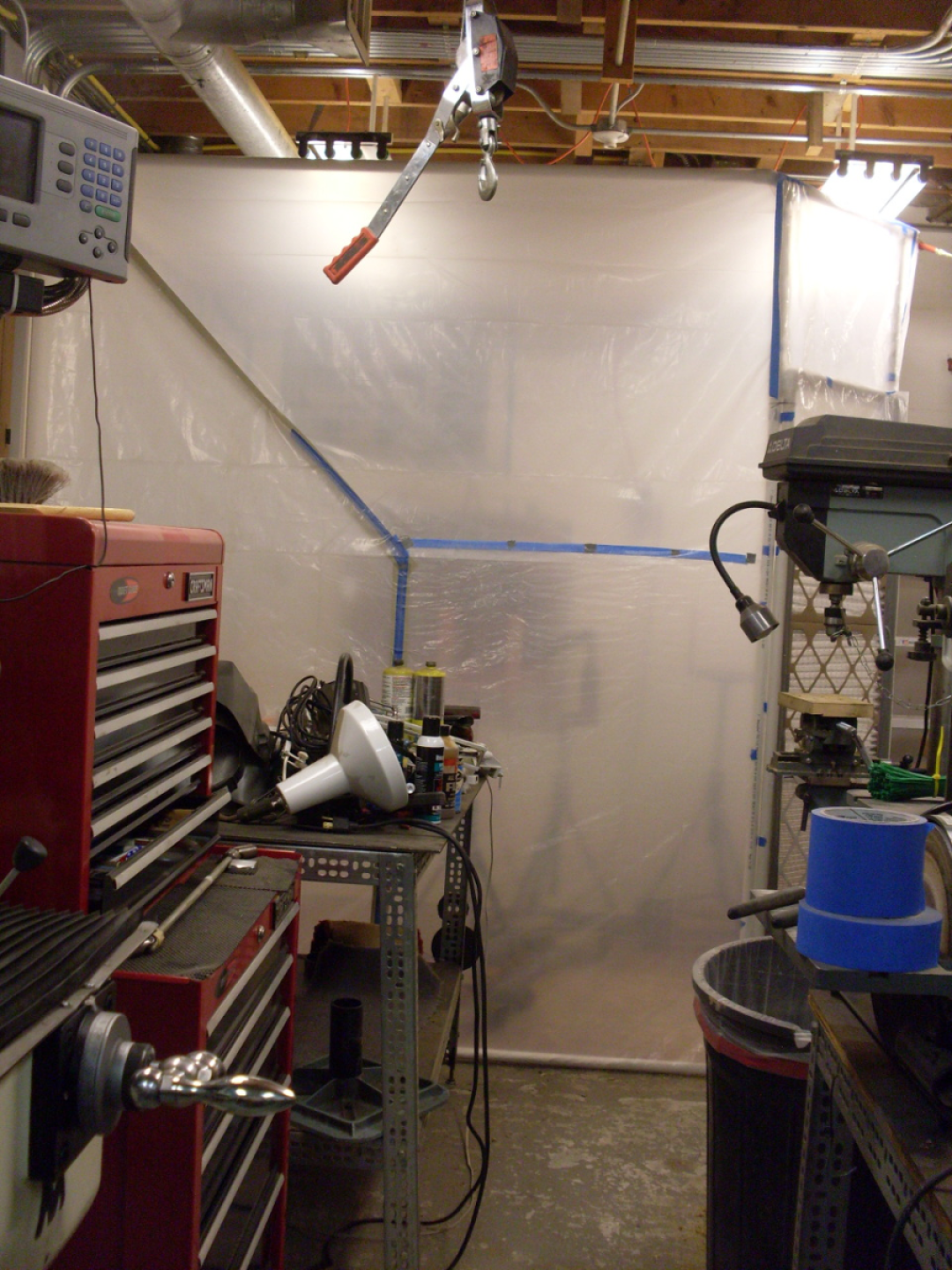

I set up a temporary spray booth in my basement shop. My first inclination was to set it up in the garage or outside, but the shop eventually won out since it would be more protected from the weather. The booth is just a frame 8' x 10' x 8' high made from 1" PVC, then covered with polyethylene sheet, taped at the seams. One side of the booth was up against a shop wall with a window in it, and I mounted a good sized box fan in the window, blowing out. This makes a negative pressure booth, the only kind that makes sense for an indoor booth since I don't want the paint fumes in the house. Plus, this arrangement meant that the air coming into the booth would be pre-conditioned and pre-filtered by the house HVAC system. I fashioned a door for the booth out of more PVC tubing, and filled in the door with furnace filters for extra filtration. The fan worked so well that when I first turned it on, the plastic walls bowed in about a foot, making the booth considerably smaller. Plus, there was quite a breeze coming through the filters. A speed control on the fan took care of that. I ran an air hose to the booth and down to a pressure regulator/water trap mounted on the wall. It was hard to get a good pic of the booth since all the stuff it displaced was crowded around it. Lighting in the booth wasn't a problem. There were two existing four tube fluorescent fixtures above it and the plastic film gave a nice even light.

Follow

1.2K

Follow

1.2K