Harley-Davidson has filed a patent for a new engine design that uses variable valve timing. Officially, the patent is not specifically for a VVT system but rather for a modular engine balancer that mounts on either side of a crankshaft. The patent does however describe how the VVT phase timing is incorporated into the balancer module.

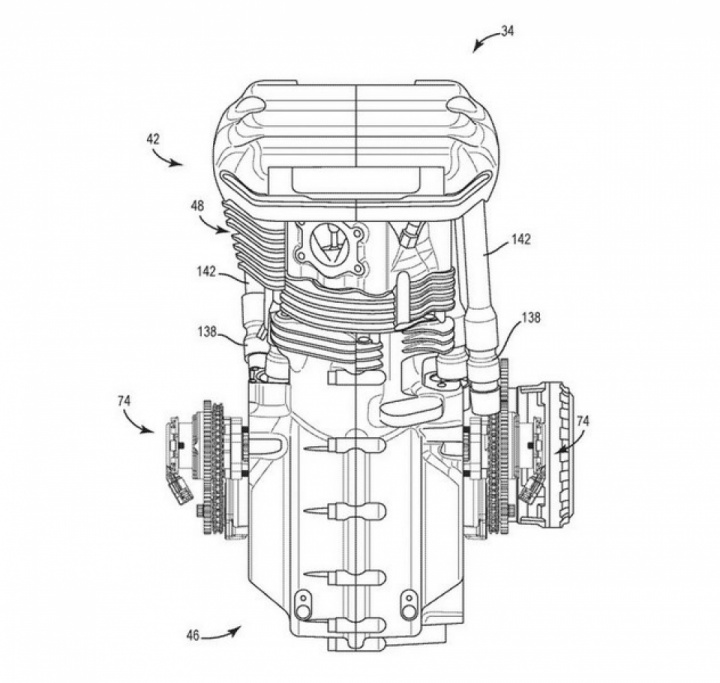

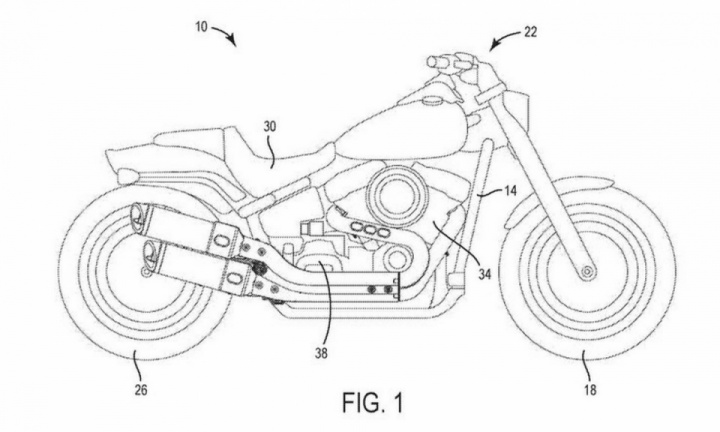

The patent uses a rough drawing of a Fat Bob, but only as a general example of a motorcycle. The engine details, however, show clear differences from existing Harley-Davidson engines. The new engine design still uses overhead valves, but with pushrods running on opposite sides of each cylinder, which matches a design in a separate patent we uncovered last August. Both patents were originally filed with the U.S. Patent and Trademark Office in early 2019, with Harley-Davidson engineer Johann Voges as the only credited inventor, making it likely they’re for the same engine.

The drawings show air-cooling fins, though the fins have uneven contours, curving in and out at at different spots around the cylinder. There’s also no oil filter at the front of the engine. It’s difficult to get a sense of proportion in these patent illustrations, but it’s possible we’re looking at the replacement for the ancient Sportster engine.

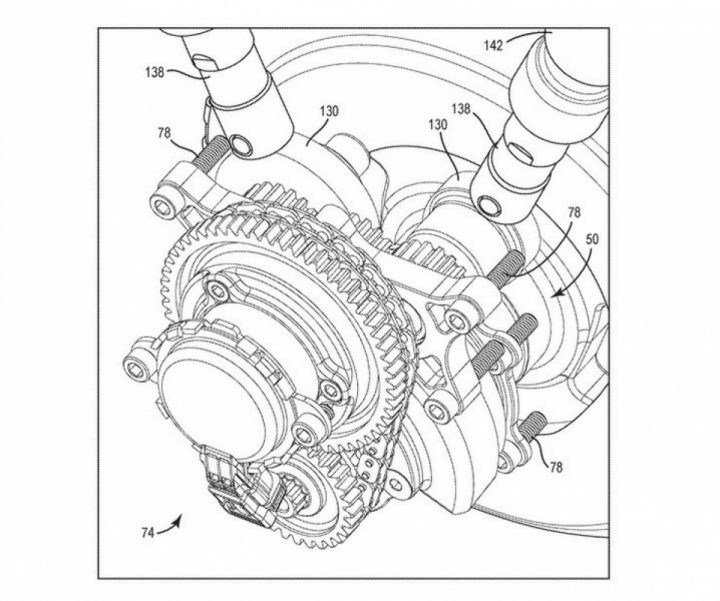

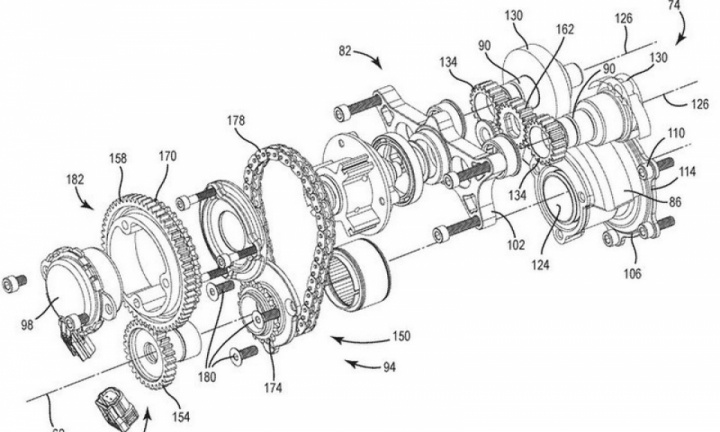

The key to this patent is the engine balance module (#74 in the diagrams and shown in exploded view below). The crankshaft is connected to gear #154 which rotates cam gear #158. The cam gear is connected to a second, smaller toothed gear #170 which rotates a chain (#178). The chain in turn spins a balancer sprocket which rotates a balance weight (#86) around the crankshaft in the opposite direction of the crank’s rotation to counteract the reciprocating motion of the pistons.

A variable valve timing unit (#98) connected to the cam gear adjusts the timing of the cams, affecting the timing of both the intake and exhaust valves relative to the crankshaft. Generally speaking, adjusting the intake timing can optimize power and torque delivery at higher or lower revs, but the likely goal for Harley-Davidson is to reduce emissions.

As it stands Harley-Davidson’s existing engines, the Sportster line-up especially, will not meet Euro 5 standards, meaning they will no longer be allowed in Europe by the end of the year. Several manufacturers have asked for the deadline to be extended due to delays caused by the pandemic, which that may give Harley some breathing room if the new engine is not yet ready.

Original Source [stateofpress]

#Moto #Bike #Technologies #HD #Harley