SWINGING ARM REMOVAL

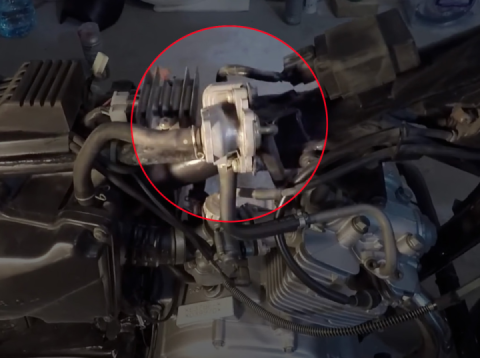

I have read that removing the swinging arm spindle is the single most difficult task to do on a Tiger Cub. So far I have sprayed it with WD40 and given it a tap with a hammer and drift, with no movement at all. The next attempt will be with penetrating oil, heat from a gas torch and a home made pulling device, made from odds and sods I have lying around.

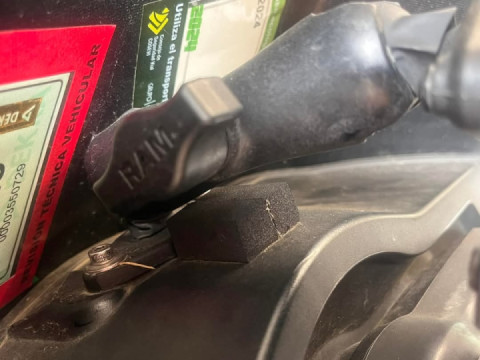

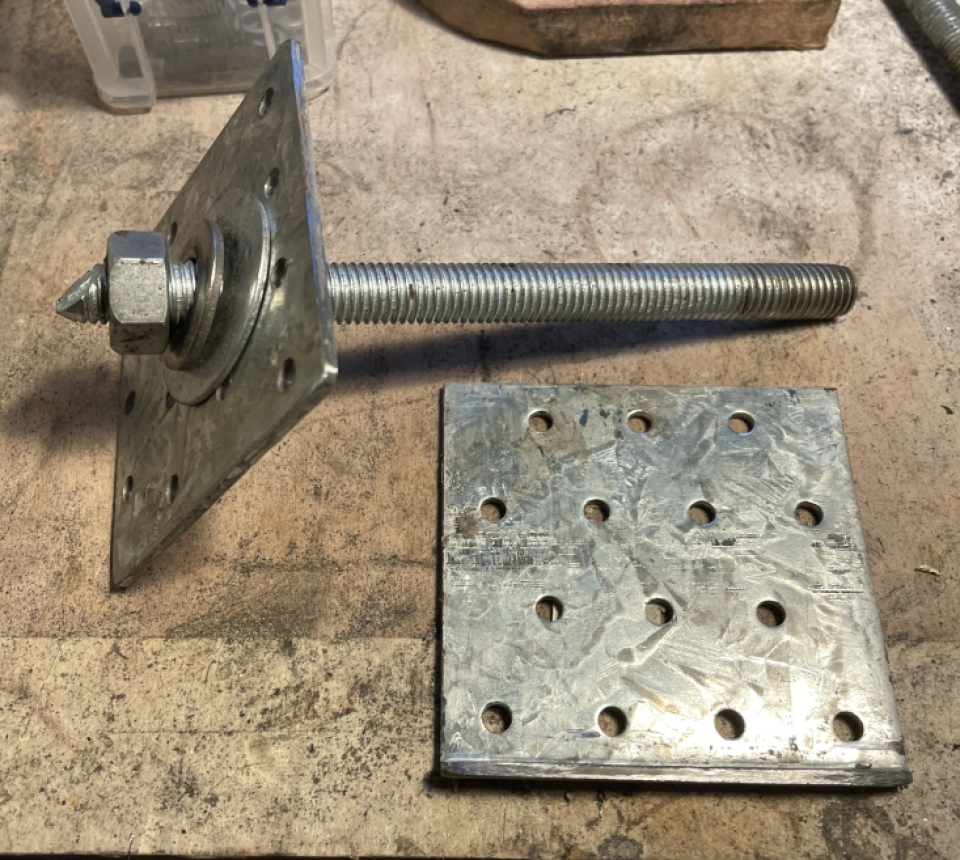

I have cut a piece of square tube from an old railing corner post from our roof terrace. I have now welded the bottom plate to the tube and cut a length of threaded rod.

When I get the swinging arm end bolt home I will have to weld it on to the threaded rod of my device and then weld a nut on the other end of the rod so I can use a spanner to stop the rod turning when I turn the other nut. I removed the grease nipple and filled the inside of the frame spindle enclosure with penetrating oil ready for my later attempt to remove the spindle.

I have brought one of the two spindle bolts home, time to weld.

The device is finished. It looks like crap but hopefully it will do the job.

Or not as the case may be. I screwed in the swinging arm bolt and started to tighten the device, I had forgotten to bring down my 5lb hammer and my gas torch so had to tap my drift with a small hammer. A few turns of the nut and a tap with the hammer and drift, nothing.

A few more turns and snap. My weld looked crap and was crap, next time I'll knock off the slag and take a proper look before using it. I will try one more time with my repaired tool, a torch and a large hammer and drift. Just in case it doesn't work, I have a back up plan, I telephoned Ace Classics and asked if they could remove the spindle. They said yes but didn't give a definite date that they could do it. One more try and then its time to take the frame to Ace.

Time to fix a tool, I re-welded the swinging arm bolt onto the threaded rod and tried again. Unfortunately I had the same result, so I picked up the gas torch and 5lb hammer. Looking back I should have tried this first, after 2 minutes of heat and a good couple of hits using a socket extension as a drift, the spindle started moving. Another minute of hitting and it was out. One happy biker!

Follow

1.4K

Follow

1.4K