Part 2 - Honda Transalp - repair

After putting the chains in place, I replaced the old clutch disks with new ones.

On washed pistons - original sets of rings.

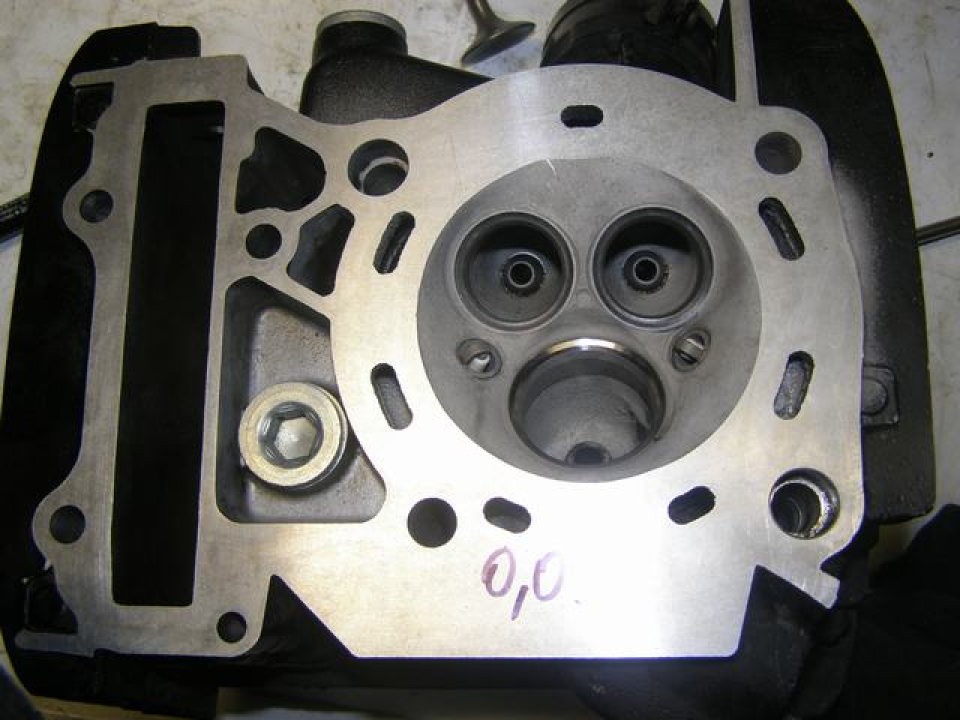

As you can see from the photo, the scuffs and scratches have been polished out.

The engine was assembled using a set of gaskets that were NOT original, which I hate. As with the chains, it was impossible to get the originals. Even ordered from various places, they did not come from this engine.

Everything happens in the reverse sequence and is not difficult.

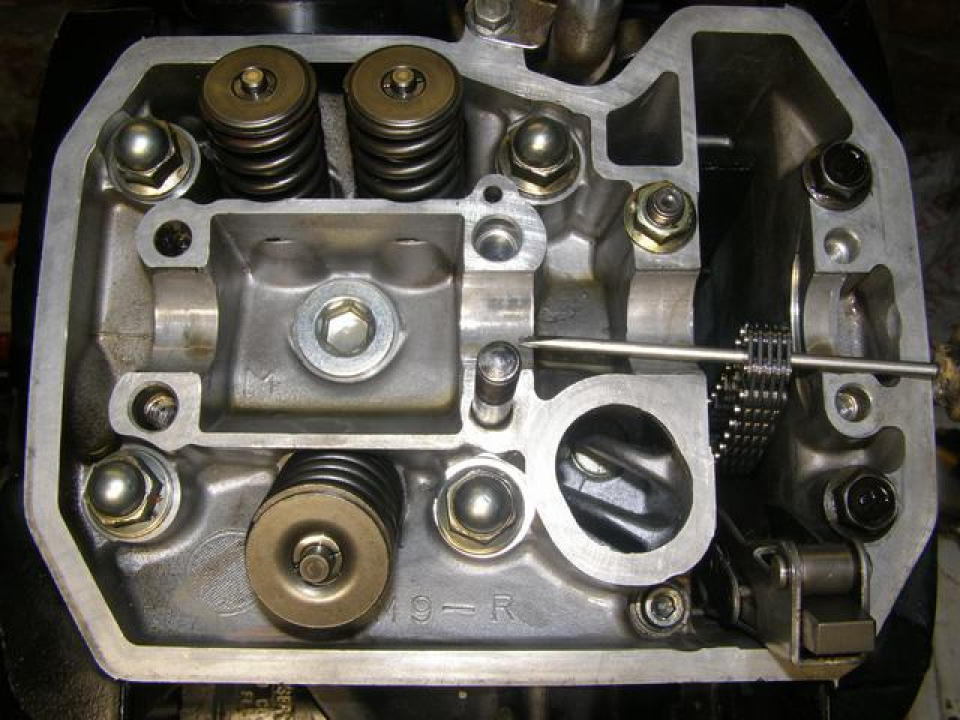

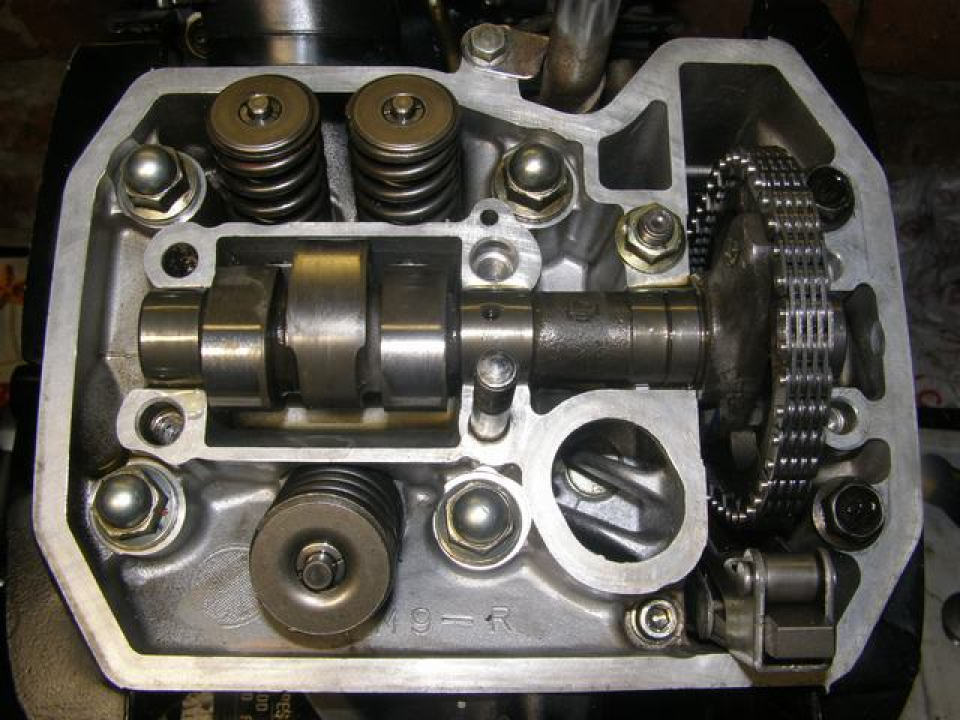

Cylinder heads were subjected to standard cleaning of carbon deposits, surface grinding, profiling of valve seats, replacement of oil caps. Valves - similarly, cleaning, and profiling. By the way, all these works I perform on new, high-precision equipment, and the result you can see for yourself.

After profiling, the valves are not lapped, but simply reassembled.

Remember that the cylinder head should only be clamped with a torque wrench to a certain torque.

The valve clearances can then be adjusted.

Insert the dipstick:

And turn the center screw until the desired clearance is achieved. Be sure to tighten the lock nut to the torque specified in the manual.

I will not talk about replacing pads, brake fluid, caliper flushing, carburetor synchronization in this article, in my opinion there is more than enough information and it is very easy to find.

Follow

2.1K

Follow

2.1K