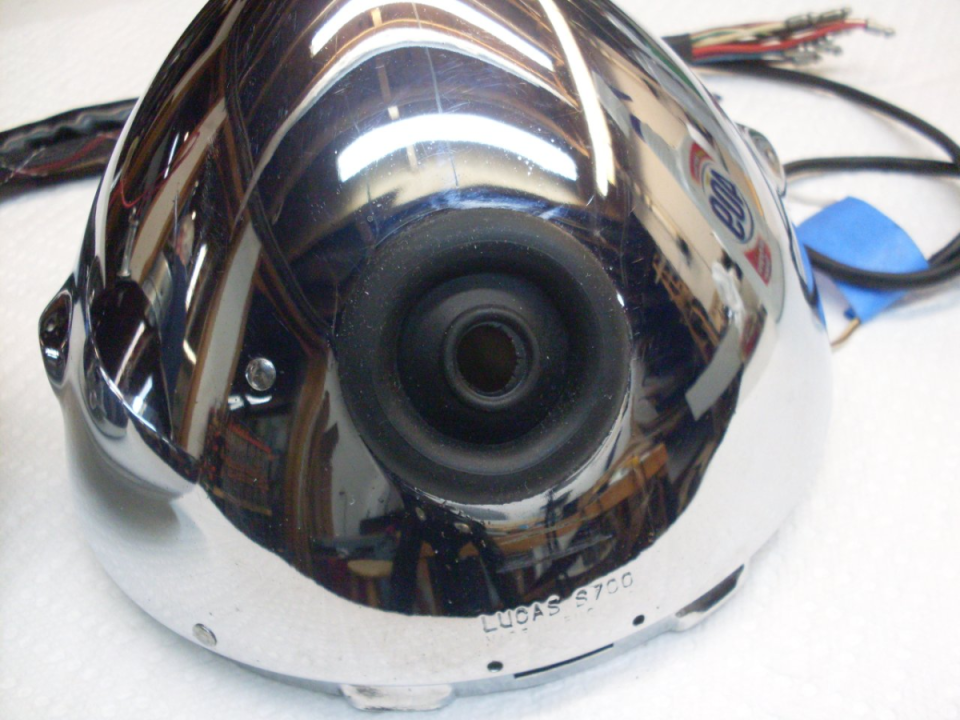

Headlight Shell Assembly

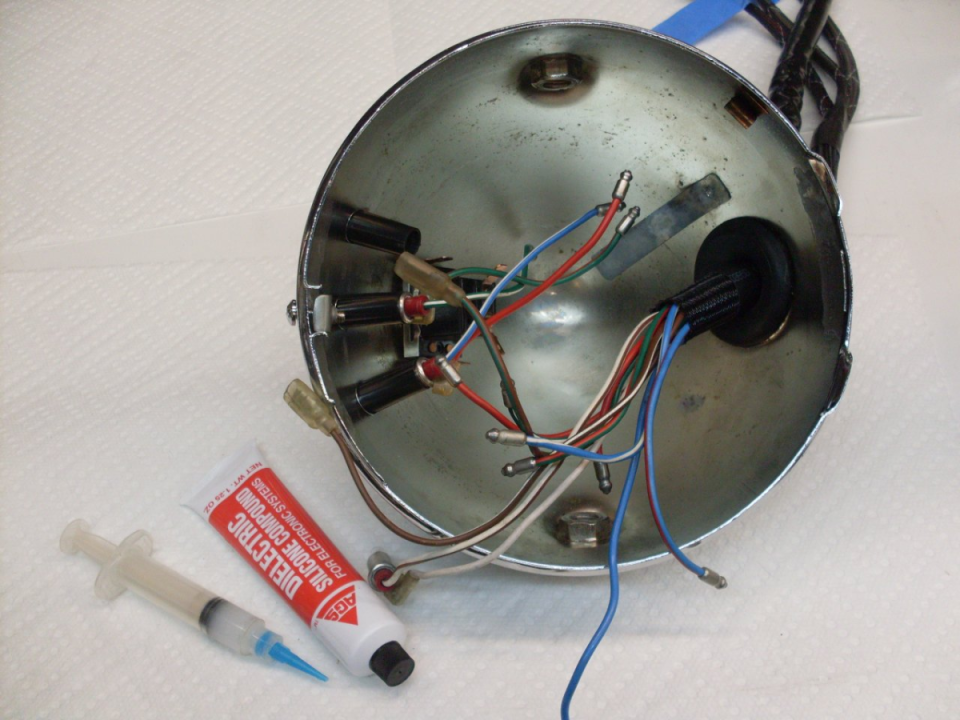

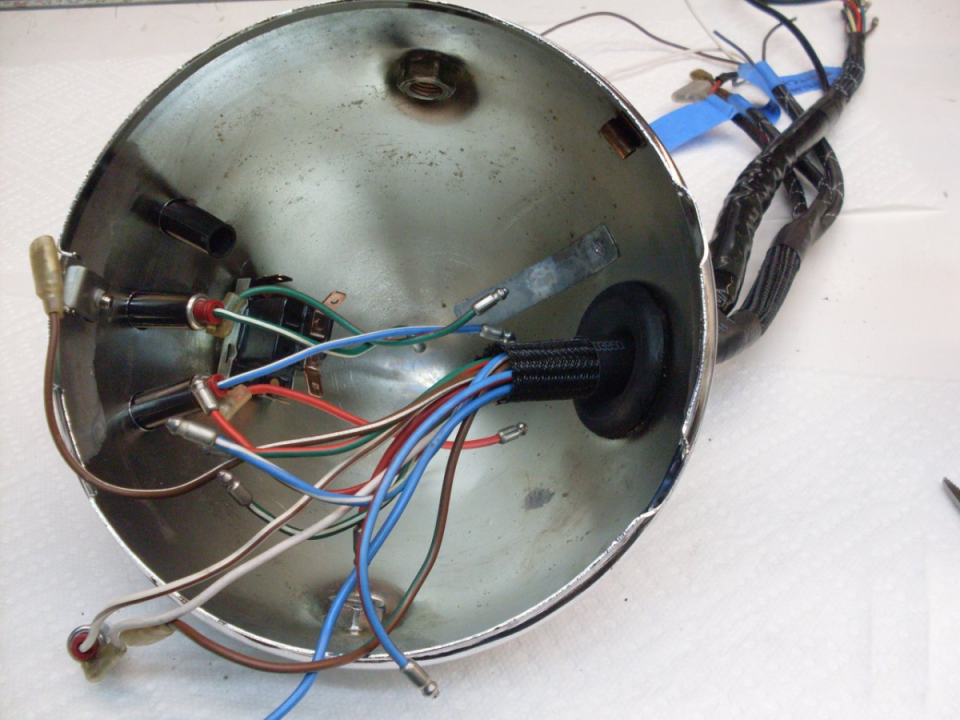

Here are the pieces of the headlight bucket assembly and front wiring harness. Installed a new weather grommet.

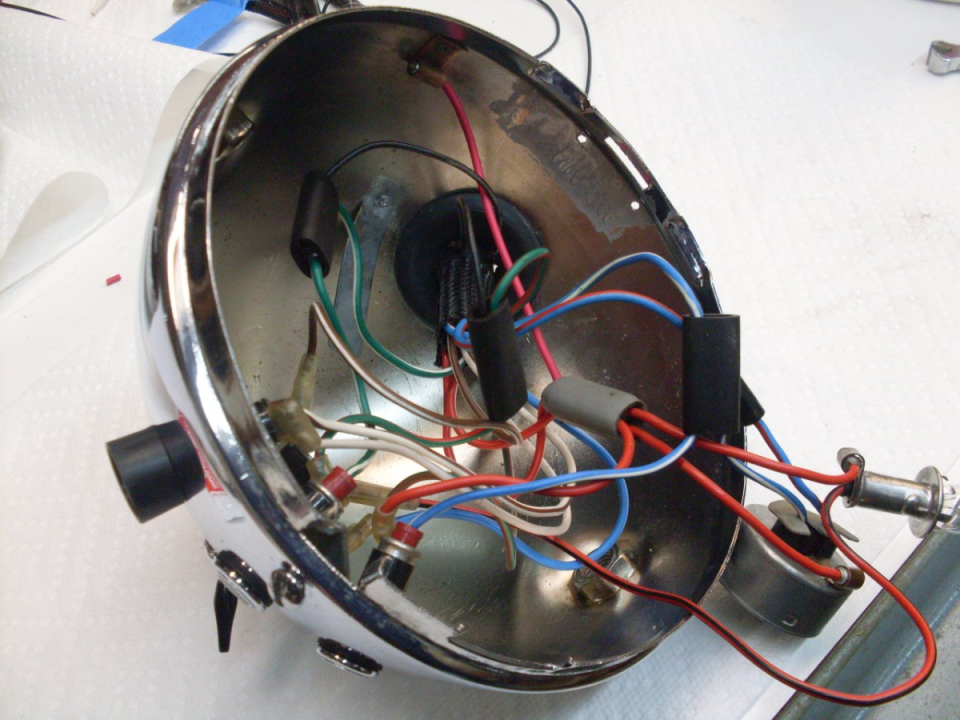

I used a dielectric grease on the electrical connections. There is a lot of misunderstanding about dielectric grease. First of all, it's not conductive. In fact, dielectric means insulator. Dielectrics are specialized materials developed to use around high voltages. The low voltage wiring on a bike or a car doesn't need the dielectric properties of dielectric grease. However, there are other properties designed into dielectric grease that make it useful for protecting these kinds of connections. First, it stays put within the temperature range we expect. It won't get thin and flow out of the connection when it gets hot. Second, it's stable. It doesn't degrade over time and change its properties. A coating of grease on a connection keeps moisture and pollutants away from the conductors. If there is proper contact force, the grease won't interfere with the electrical connection. The grease can also help reduce the insertion force needed to seat the connection.

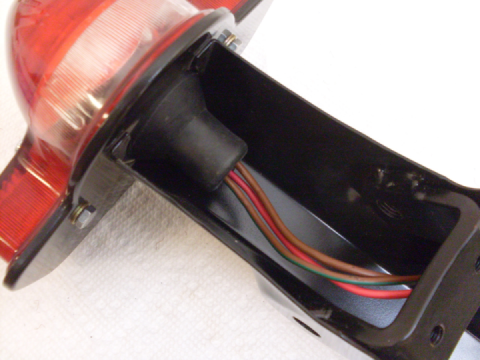

Other than wiring to the light switch, it's pretty much just matching color to color inside the shell. Normally, wires from the front turn signals come into the shell to connect. Since they aren't ready to go yet, I made some black wires (for appearance) to connect inside the shell, and routed them outside. I'll connectorize them somehow so that I don't have to open the headlight shell to connect the signals.

The headlight shell mounting brackets and hardware.

The mounted headlight assembly. The rubber mountings for the headlight brackets are new, too.

Follow

1.3K

Follow

1.3K