Throttle Control and Handlebars Part 2

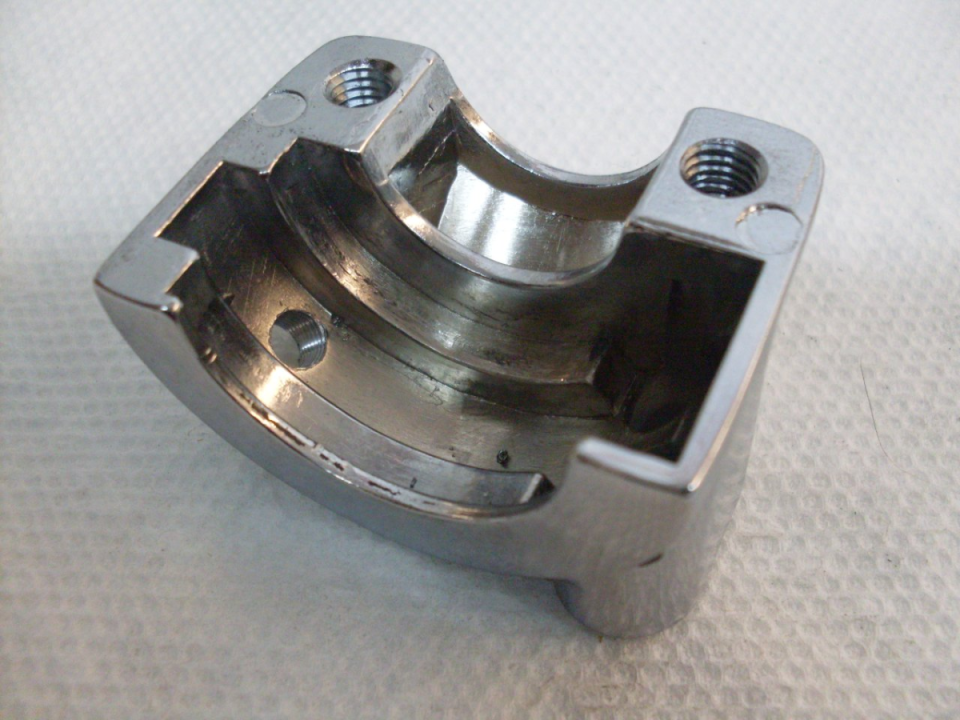

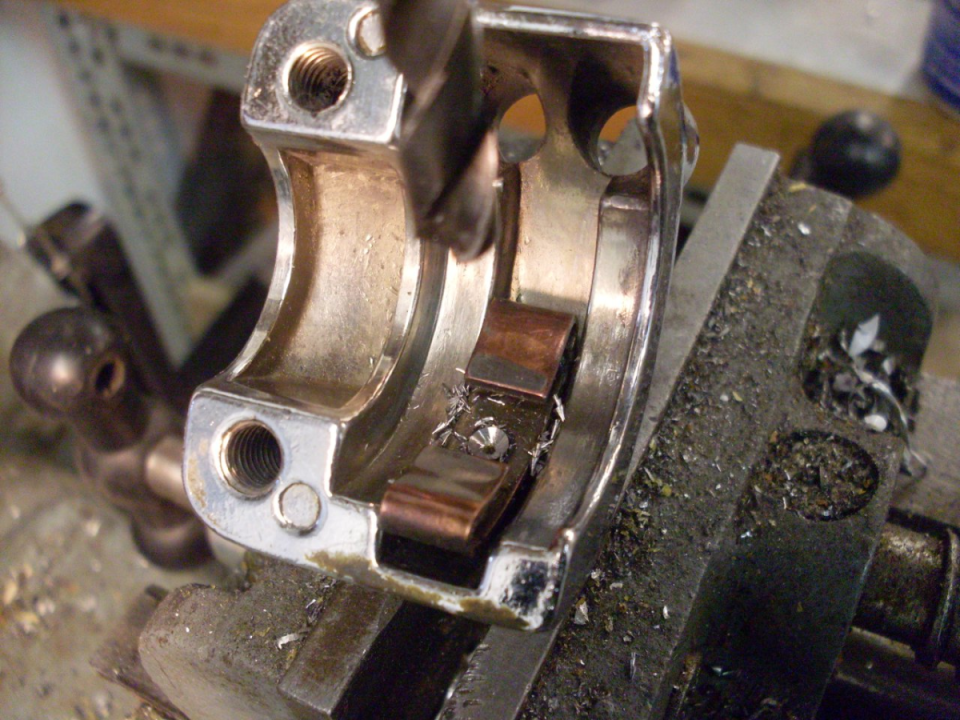

I determined that since the original screws are enough larger than the repro ones, that I could drill and re-tap the body for the original screws. After buying the special taps, I probably would have been better off having the old parts replated. Pic shows retapped holes.

Since I didn't think I was going to re-use any of the throttle twist grip assembly, I wasn't too gentle when I removed the stubborn grip from the rotor. I ended up damaging the soft pot metal rotor. It had a dent in it and was slightly out of round so that it wouldn't slip freely over the handle bar. I made this 7/8" mandrel to shove down through the bore and straighten and align it.

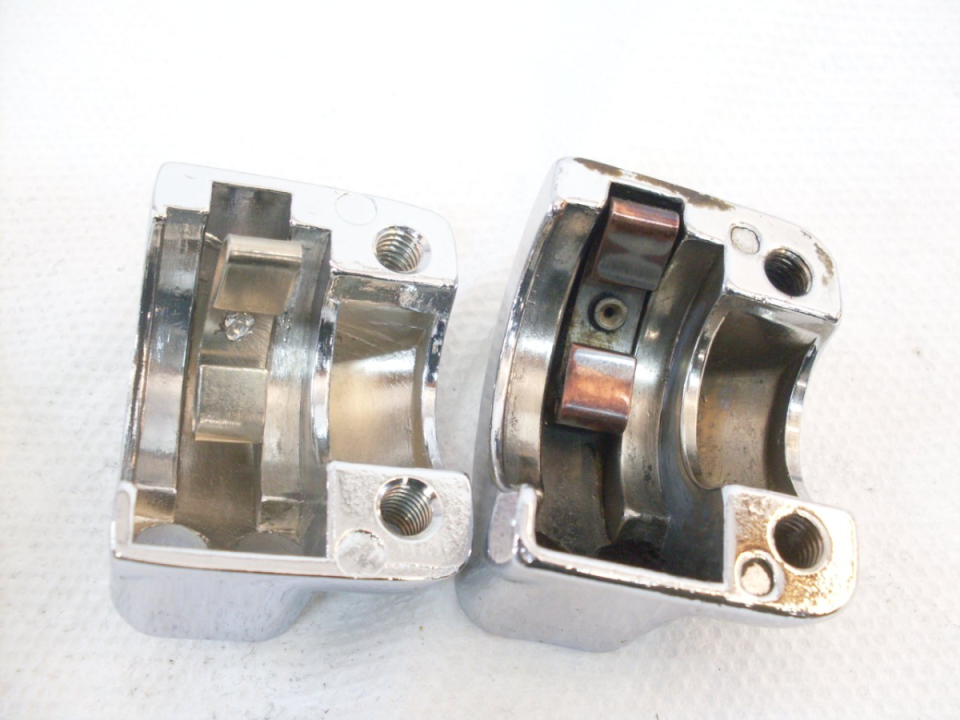

The friction springs on both units were staked to the end of the adjustment screw--the original with a nice "V" deformation, while the end of the repro screw was just mashed down. The original spring was also more robust and shaped to mate with the rotor better. Since I was going to move the original screw to the new body, I had to remove both springs. I'll have to be machine the original screw to lengthen the staking nipple.

The thingy on the right of the left picture is a little split bush, tapped 7/32-40 to accept the friction spring screw. When tightened in the lathe chuck, it tightens on the screw threads, holding it securely for the forming of the stalking nipple on the end of the screw. The right picture shows the lengthened nipple. It's also drilled to make it deform easier. Last pic shows the hardware with new zinc, ready for assembly.

I used a transfer punch as a tool to musroom the stake just enough that the spring woudn't fall off.

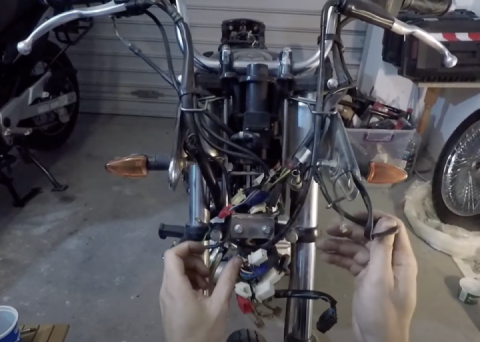

A lot of unanticipated work went into this assembly. The geometry of the new body halves was different enough that I had some binding of the rotor when everything was tightened down. Took some time to figure out where the rub was and fix it.

Follow

1.2K

Follow

1.2K