Chain Guard

Working on a few miscellaneous things recently, including the chain guard.

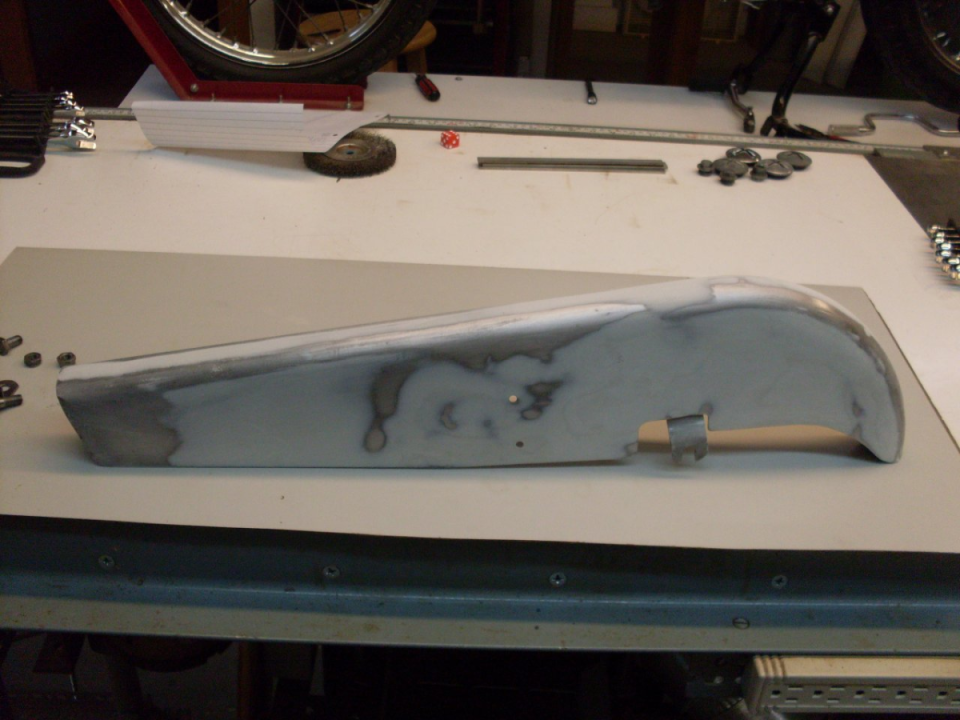

Forgot to take a before picture of the chainguard, but it was basically intact with the paint tired and dull, and the inside caked with ancient oil and road grime. There was some rust around the edges, but no apparent real damage. After cleaning it up and stripping the paint off, the only real problem with it was an area along the lower edge was "oil canning", which means that it would pop in and out of position with a little pressure. Also, on looking closer, the bottom edge of the sheet metal was wavy. These are symptoms of stretched metal in that area. Whether this was the result of some damage that wasn't apparent, or an artifact of the manufacturing processes (I suspect the latter), I thought I'd try my hand at some metal shrinking. The process involves rapidly heating small patches in the stretched area, and then cooling them quickly with a wet rag. I believe the idea is that as the small patch gets to red heat, it tries to expand, but the surrounding cooler metal constrains it, so the hot metal, more pliable now, just compresses in area (thereby getting a little thicker). Cooling the spot quickly freezes the shrunk patch. This is repeated all over the stretched part of the surface. At forst, I tried a propane torch, but I think it was too slow, so the pliable area wasn't localized enough. Oxyacetylene worked nicely.

After this process, the surface was distorted and discolored, and looked worse than when I started, but the oil canning was gone, and the bottom edge was actually straighter. A little work with a hammer and dolly and a file, and I had the surface pretty flat.

A little Bondo helped to flatten out the entire surface, and I also filled in the seam along the top of the guard for a cleaner look.

A few coats of black lacquer, and a few more of clear, a little rubbing, and I have a decent looking chain guard.

Follow

1.4K

Follow

1.4K