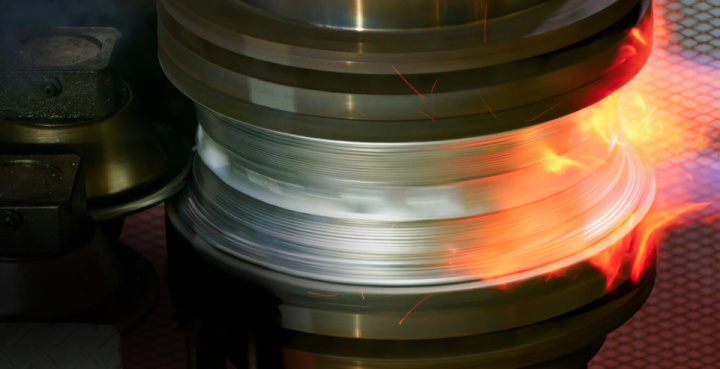

A pre-formed aluminum wheel is attached to a round fixture and begins to spin on a mandrel. A burner on one side ignites and heats the wheel body while a roller on the other side extends out and begins to shape the rims by pressing against the wheel. It moves up and down like a human hand, stretching and forming the aluminum workpiece.

As the heat and pressure are applied simultaneously, the aluminum begins to take shape on the mandrel in much the same way a potter works a lump of clay into a delicate art piece on a pottery wheel, with small indents and fine contours gradually coming to life. This flow forming process is how Yamaha’s SpinForged Wheels for the new MT-09 were created. Already a pioneer in the casting of lightweight aluminum alloy wheels, Yamaha is again opening the door to a new realm of motorcycle chassis manufacturing.

A long-held ambition among the engineers and craftsmen at Yamaha’s Monozukuri worksites was to spur innovation from the factory floor. They apply their skills and expertise toward taking the challenging demands of the developers and turning them into reality. Naturally, it is one way they show just what they can do and it remains the bedrock for taking Yamaha products further. However, there was a growing desire to go a step beyond the usual advancements and bring about more dynamic innovation.

To show how changing the wheels could bring innovation to the motorcycle, they called on ideas, technologies and techniques that had been on the backburner for some time in a new challenge. The lightweight wheels of the 2021 MT-09 were made possible thanks to two major endeavors. The first was the research into and selection of the right aluminum alloy and the second was the decision to use flow forming to machine the wheels. The engineers surmised that making the aluminum itself stronger would help them take on this challenge of creating a new manufacturing method for wheels, and this inspired them to research various aluminum alloys.

But strength alone was not enough; the alloy also had to have lasting elongation qualities. So they dove into research and experimentation with aluminum, trying different compositions while controlling the factors for conducting heat treatments and the like. “Even slight changes to the alloy’s composition or the conditions we had in place would dramatically alter the metal’s characteristics. Aluminum is very sensitive in that respect and there is little latitude for change,” explains one engineer. Eventually, Yamaha was able to formulate a special aluminum alloy specifically for spinforging the MT-09’s wheels and devise the right means for machining them.

Flow forming has been an established method for manufacturing car wheels for some time. Because the roller presses out the surfaces, it stands as an effective method for forming wide rims. But with motorcycles, wheel rims are quite narrow in comparison and conventional casting techniques are sufficient. However, unlike automobiles where only one side of the wheel needs an attractive exterior finish, both sides of a motorcycle wheel serve as part of its design appeal, making them that much more difficult to design and machine. In short, using a typical flow forming process to produce motorcycle wheels would require much effort for little gain. But Yamaha still decided to take on the challenge to find some way to make it feasible, because the craftsmen were convinced that they could lighten the wheels to a level beyond what established manufacturing methods could deliver.

In truth, this was not Yamaha’s first use of flow forming; it was originally used some 30 years ago to manufacture the wheels for ATVs but had been shelved altogether thereafter, with no further development. As one of the engineers said, “This was like stumbling across a goldmine, both in terms of production technology and for us on the factory floor.” Thus, the pioneering spirit of the craftsmen was set alight.

Cast wheels were first approved for use on motorcycles in Japan in 1978. In the grand scheme of things, that was not so long ago and prior to that year, almost all motorcycles were fitted with spoked wheels. In fact, Yamaha was the first manufacturer to fit cast wheels to its motorcycles following this approval. That is also why a deeply held belief runs through Yamaha’s chassis engineers—we are the industry pioneers of light-alloy cast wheels, and as the pioneers, Yamaha factories should open the doors to new ideas. And that is exactly how they want it to stay.

As the wheel spins on its mandrel, the roller applies pressure to the rim to alter its grain structure in a process strikingly similar to forging. As the rims spin, they are progressively elongated and thinned until they are a mere 2 mm thick. Compared with the previous model’s 3.5 mm rims, Yamaha’s proprietary spinforging method enables a much thinner rim, and the new front and rear wheels together are some 0.7 kg lighter.

“Wheels are critical components that not only directly influence handling and performance, but also are a big factor in safety. That’s why Yamaha makes such a concerted effort to make them,” says another engineer. “As makers of cast motorcycle wheels, we’ve made another beneficial addition to our Monozukuri repertoire with this technology, and in the same way, something else new will be born from it in the future.”

Sourse: Yamaha Motor

#Yamaha #Moto #Bike #Motor #Technologies