Part 8 - Yamaha YBR 125: Homemade Exhaust System

Once again thinking over the project, I realized that there is no way to bypass this step, because the native YBR exhaust is too bulky and low. And what is a scrubber without an adequate exhaust? I have to fix it.

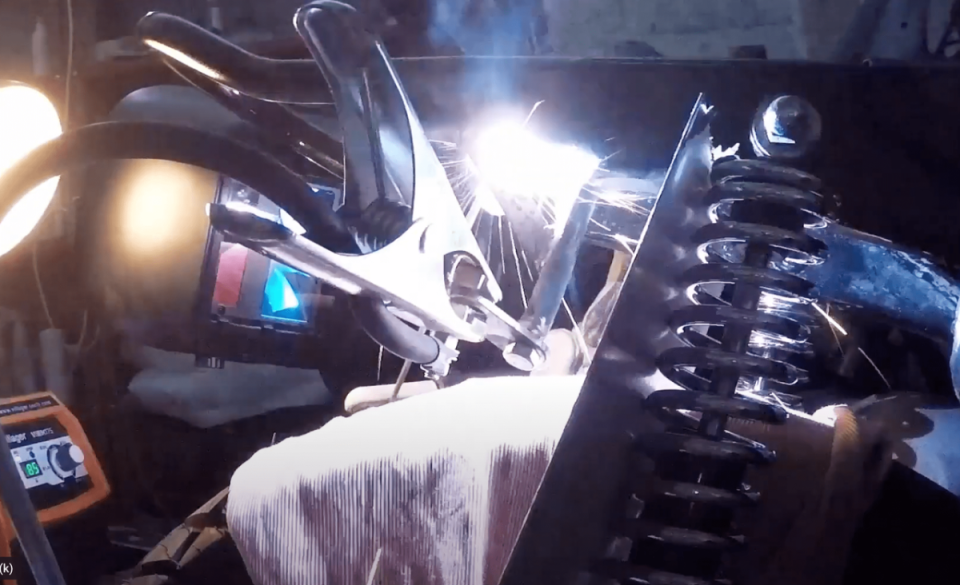

The first thing I did was to buy a small Chinese can (not straight-through) on ebay and welded a small mount for it in the tail section, using a protruding remnant of the YBR trunk and reinforcing it with a brace. The welding was a bit of a mess, there was a lot of slag, so I double welded the welds, cleaned them up and smeared the pores with metal epoxy.

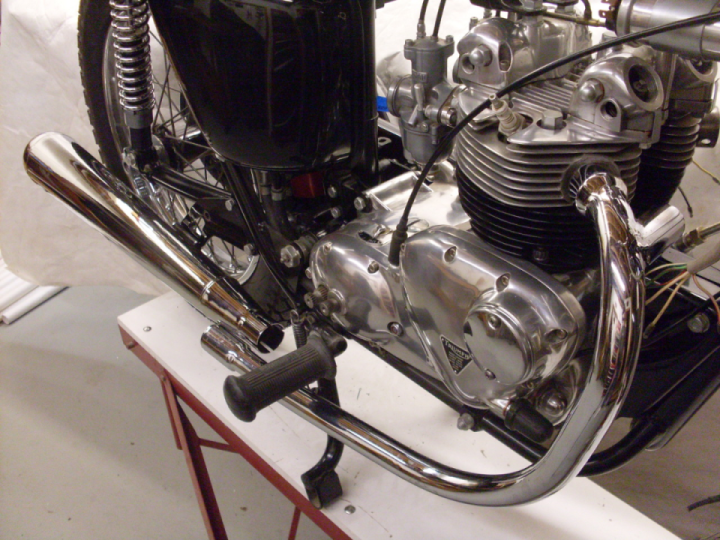

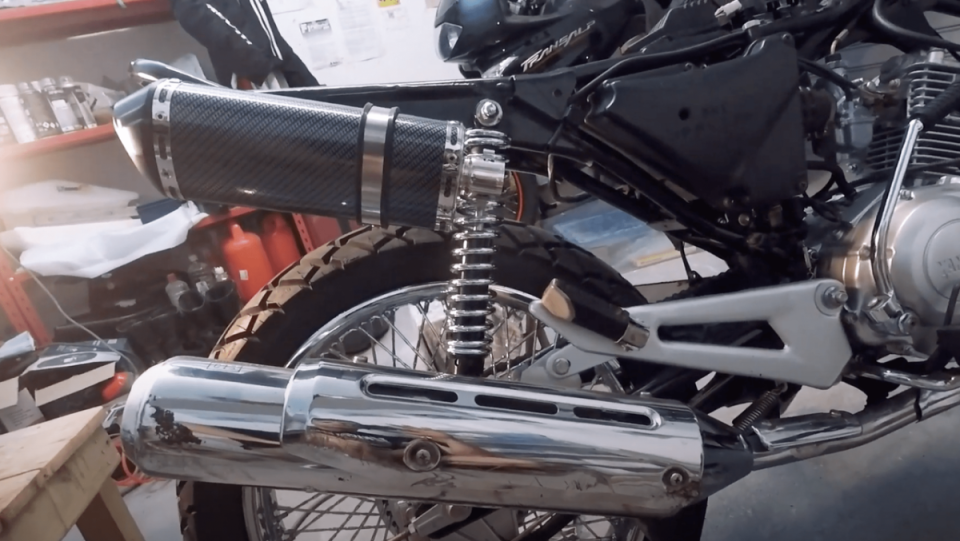

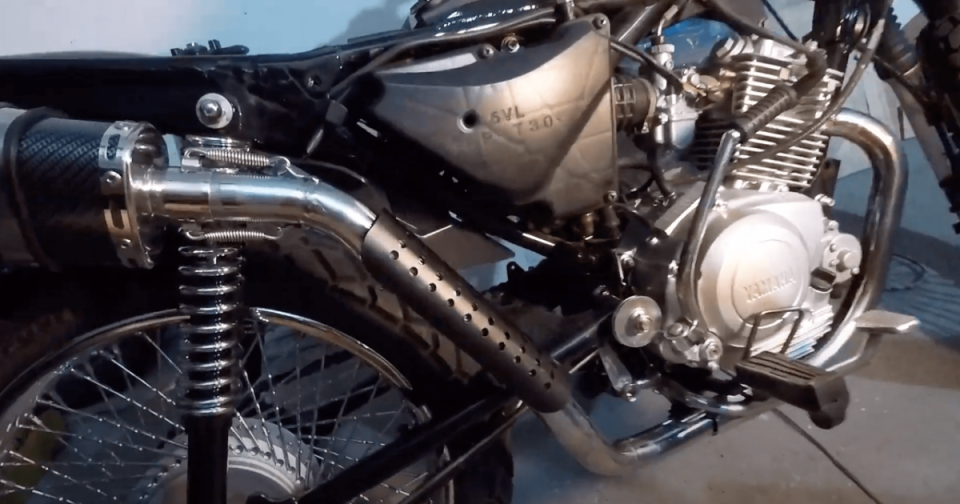

I decided to do it with "little blood": to leave half of the exhaust pipe original (from the inlet part), and to weld the rear part so that to place the new muffler at the top - almost at the level of the seat, away from the dirt. Hanging the muffler on the mount, I realized it was worth going on! - It turned out pretty lean, just the way I wanted it:

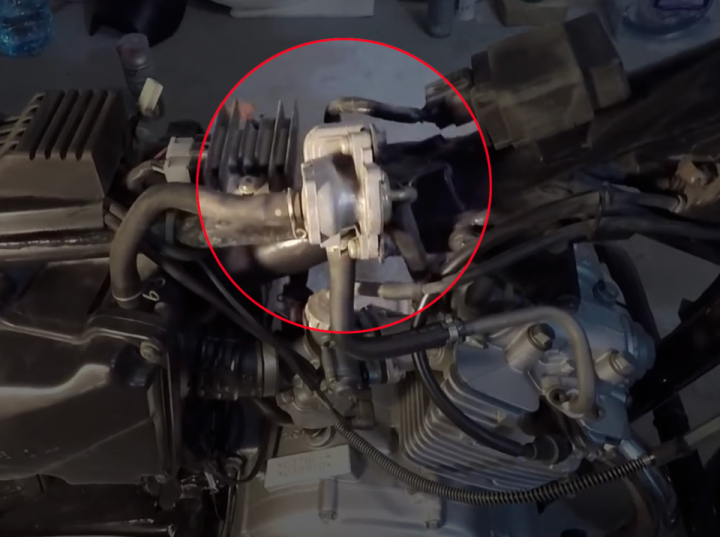

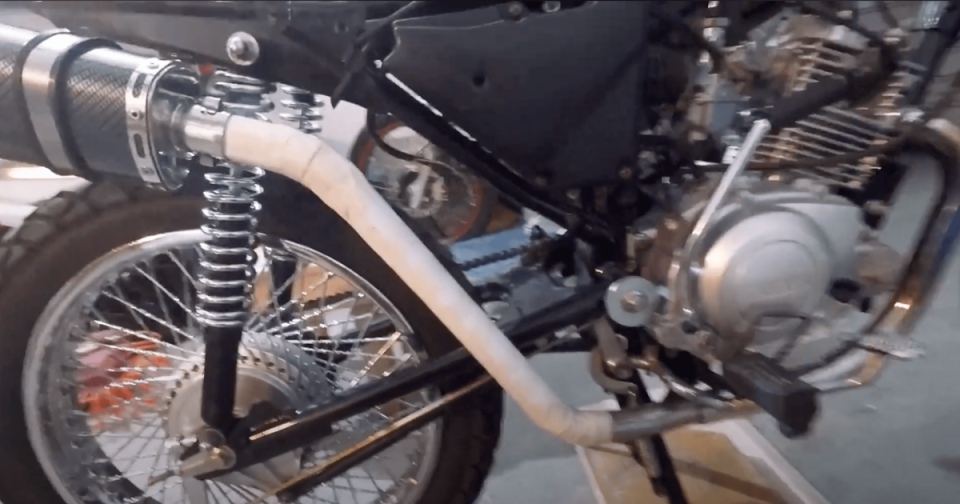

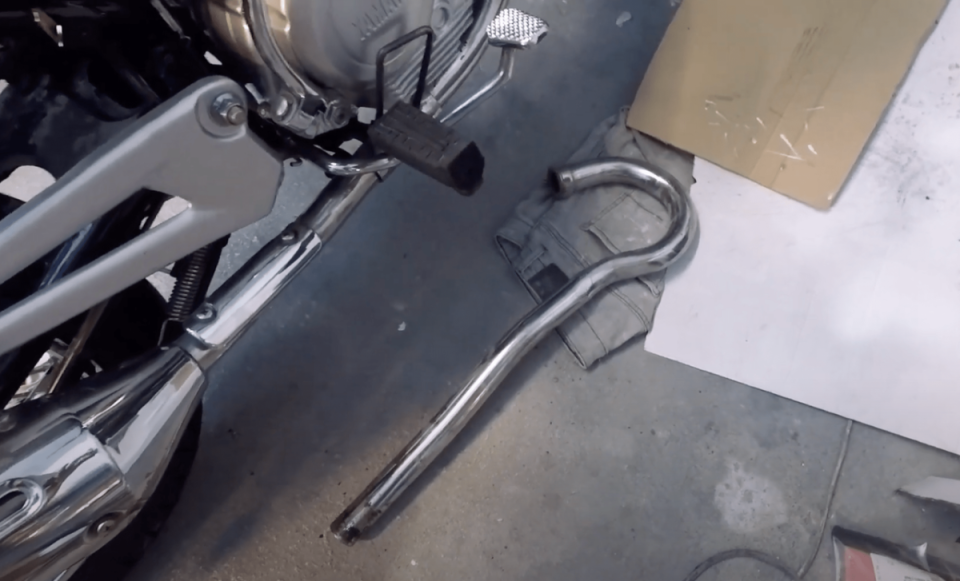

Then I drew a general sketch of the exhaust system in photoshop, picked up a donor (an old exhaust from Honda CL 350), cut off the back part of the standard pipe and all the excess from it and made this layout from wattman - to understand the future design:

And now: "Saw, Shura, saw..." - I sawed various elbows from the donor mating, as well as straight sections from pieces of the original exhaust. After that I took off chamfers, temporarily taped it all with painter's tape and adjusted it to the place:

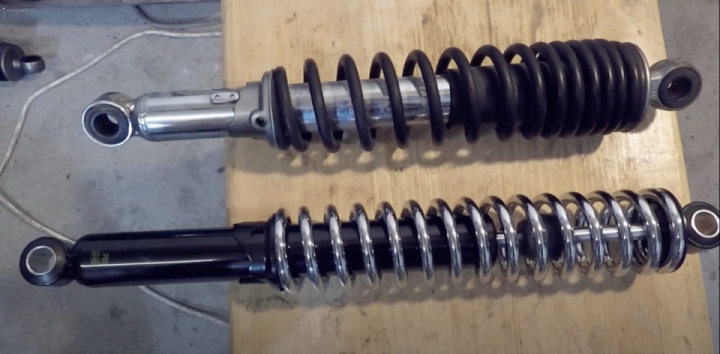

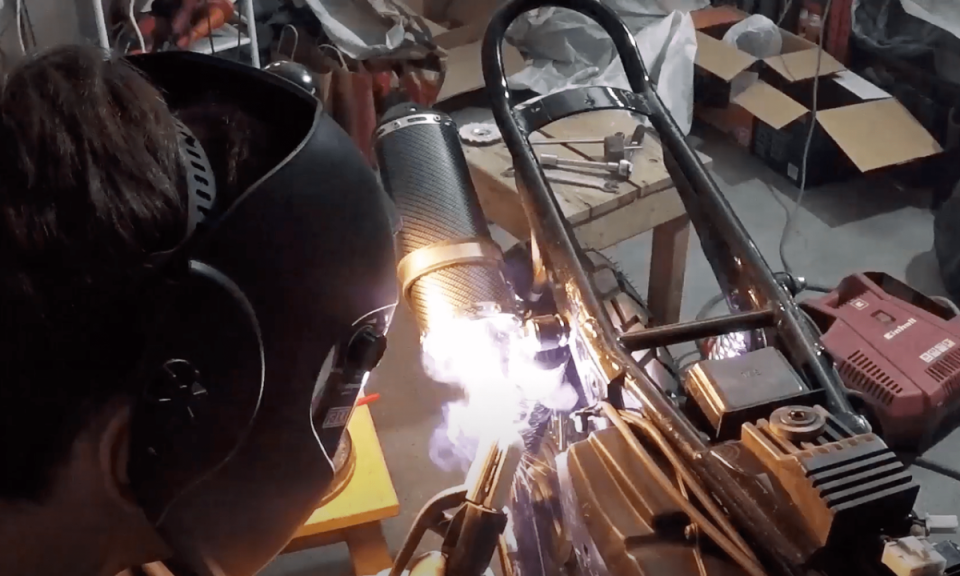

I joined all the links by tack welding - 4 points for each joint. For welding I used E308L16 stainless steel electrodes with a small current of 55A, polarity reversed. After removing the tube from the bike, everything was thoroughly welded. The lugs for the muffler mounting springs were also welded on:

After all the seams were cleaned with a bolgar - some places had to be slightly welded. And in order to minimize the feeling of collage - everything was polished with the help of felt tips on the drill and metal paste.

The test of the system was successful - the sound was quite pleasant, which I myself did not expect from a cheap Chinese can. And both with and without db-killer - clean even, low sound at all speeds!

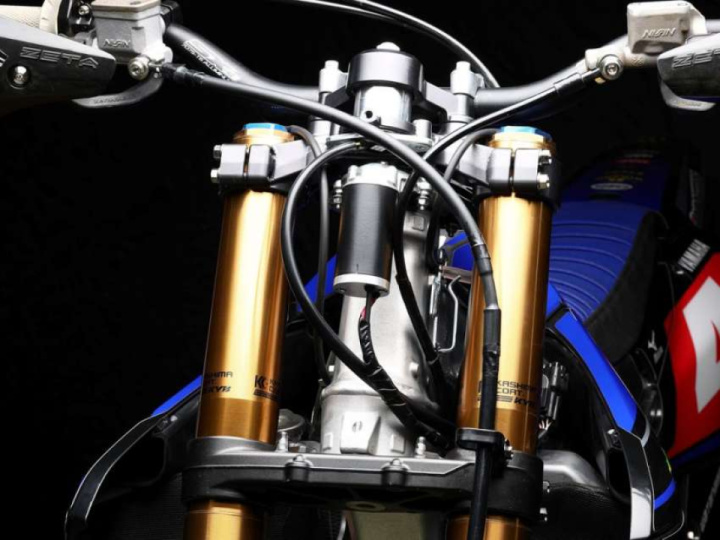

Taking into account that the design of the exhaust has changed - now most of it passes next to the rider's right foot, increasing all chances to fry it at any opportunity - it is necessary to think at least about elementary thermal protection. There was not much choice on the Chinese market: I bought the right size shields - one small one made of carbon and one longer one made of steel. To prevent the steel one from getting very hot, I additionally wrapped the pipe section under it with thermo-insulating tape:

Follow

2.3K

Follow

2.3K