Zinc Plating (2)

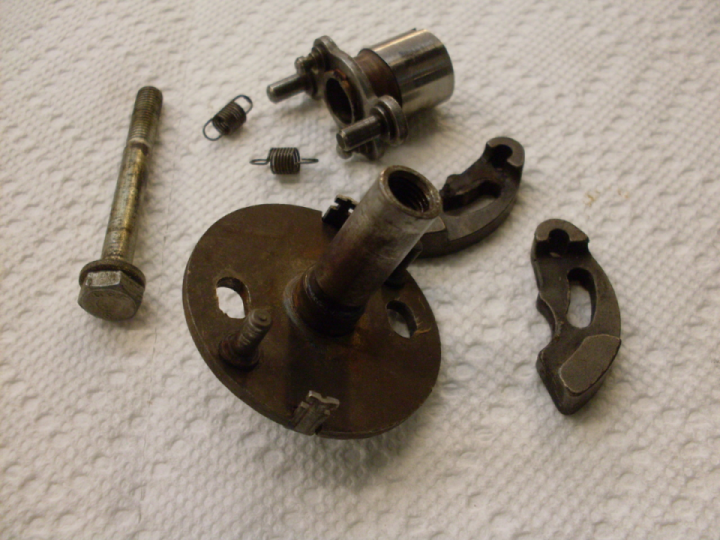

Here are the two chain adjusters. The one on the left looked like the one on the right about an hour before. I took the opportunity to clean up the profile of the part prior to plating--squaring up the outer rim and adding the chamfer.

Here's the process on the head bolts, some of which were pretty heavily rusted.

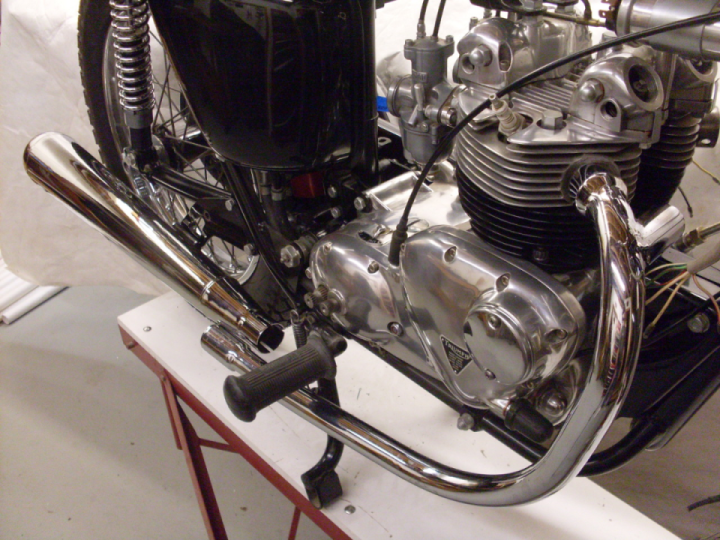

I can take a few small parts directly as they came off the bike, clean thenm up, plate and buff them, ready to install in under an hour. That's way less time than two trips to the plater.

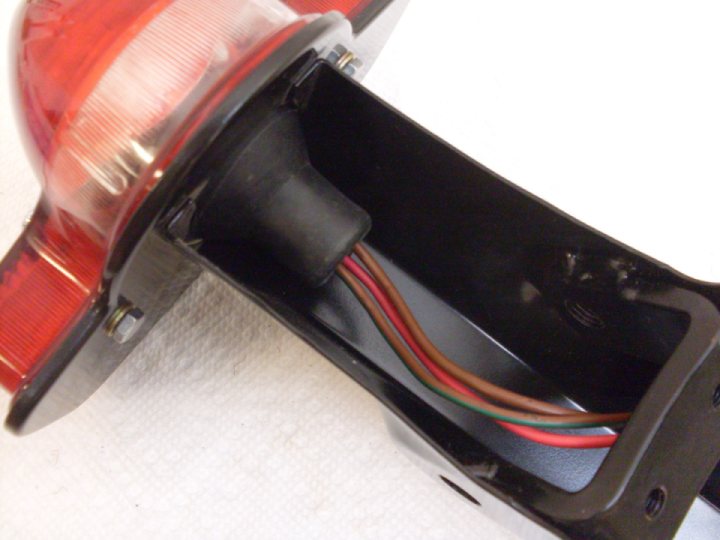

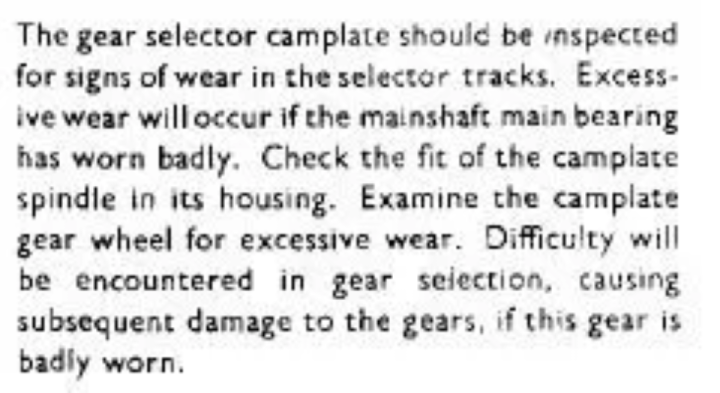

Rear Brake Lever, cleaned up and plated:

By weighing the parts before and after, I've been able to determine that I'm getting consistent coatings up to about 0.001 inch, depending on the time in the bath. Commercially, 0.001 is considered a fairly thick coating.

Zinc plating is a very good way to give some corrosion resistance to steel parts. It is a sacrificial coating, which means that even if it is damaged so that the underlying steel is exposed, the zinc can still offer protection by attracting the corrosion to itself and away from the steel.

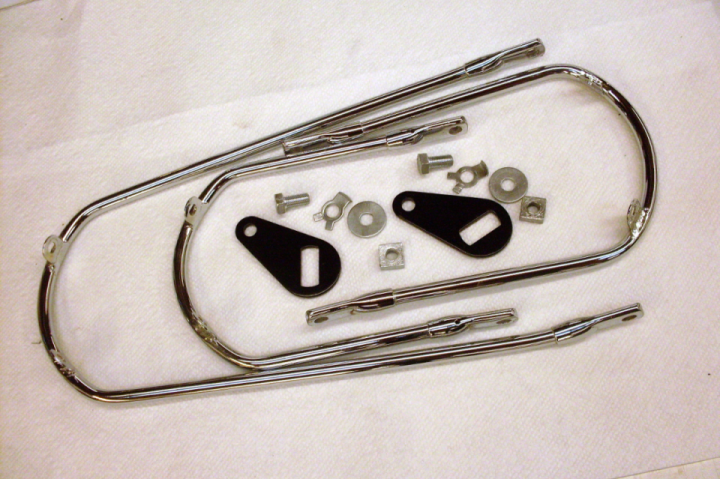

However, zinc itself corrodes slowly. To protect the zinc, there is a process called chromate passivation. It is what gives many plated parts that yellowish, sometimes irridescent look. I tried my hand at this process and here are some results. I don't particularly like the yellowish color, but the zinc won't stay shiny very long either.

On the left are the two "wedding bands" that go onthe bottom of the pushrod tubes to keep the seals from squeezing out. Both are zinc plated, the one on the right is chromate passivated. The other picture is a rocker box oil feed bolt, zinc plated, and the head passivated.

Follow

996

Follow

996