Instruments Pt. 4

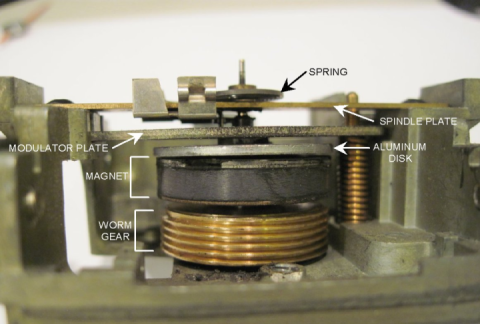

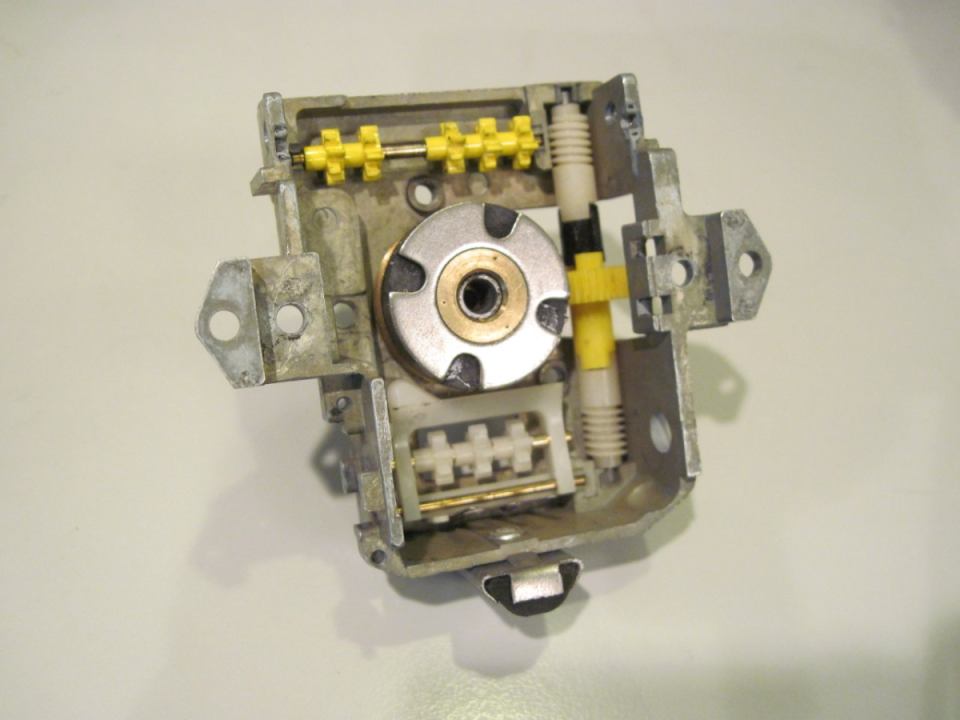

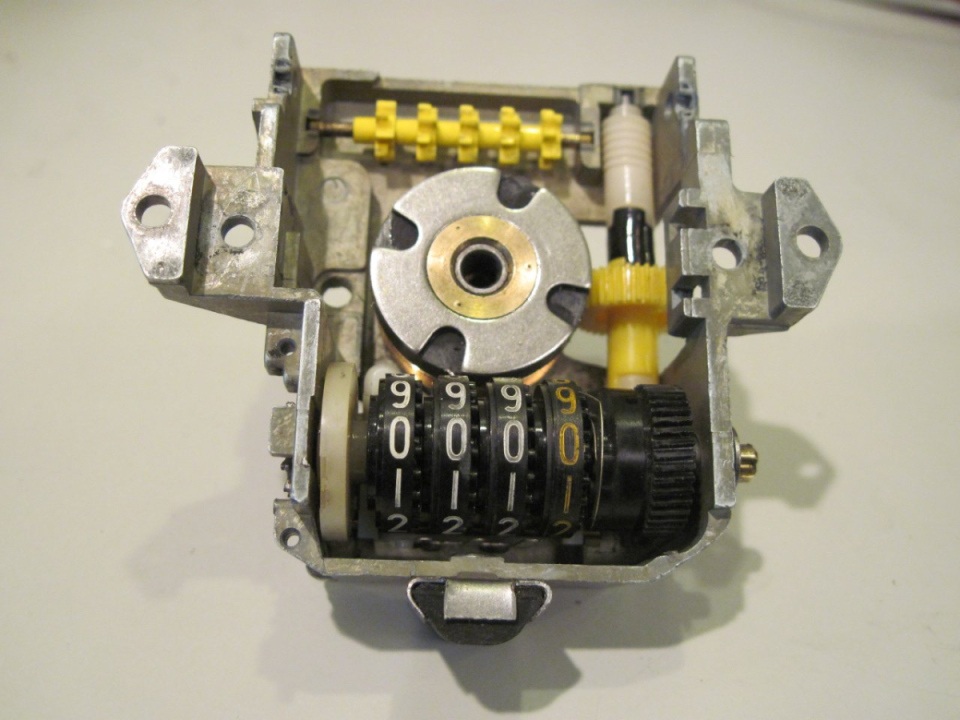

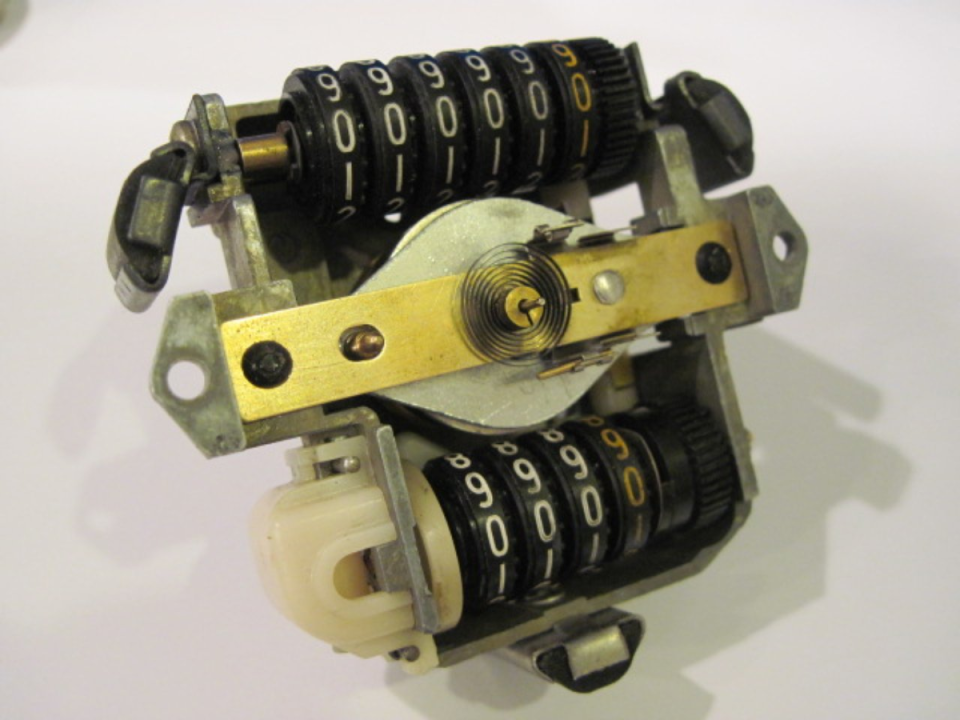

Next picture is with the input spindle installed and the worm gear and magnet pressed on. I realized one thing in looking closely at these parts. I've often heard that if a speedometer or tach inner cable is too long, it will ruin the tach or speedo by intruding too far into the guts of the mechanism. At least on these instruments, that can't happen. First, the square recess in the input spindle that accepts the inner tach or speedo cable is a blind hole. Nothing can get into the works through that hole. What can happen, though, is that since the input spindle has a flange at the bottom that limits how far it will go in, excessive force on the input spindle from an inner cable that's too long would put pressure on the flange, and cause increased wear. This would eventually but surely cause the spindle to move upward to contact the aluminum disc. Intermittent contact of the magnet with the disc causes the pointer to jump wildly, and will eventually break something.

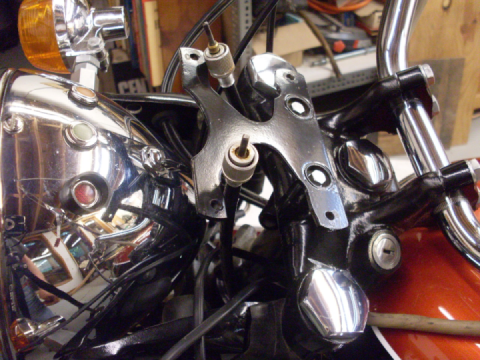

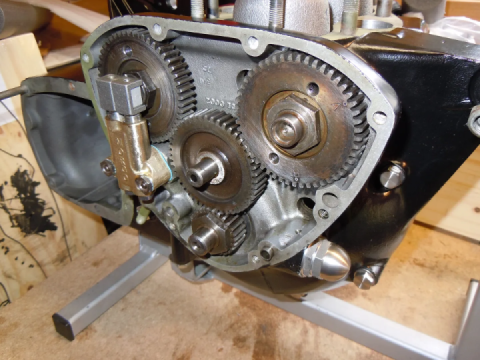

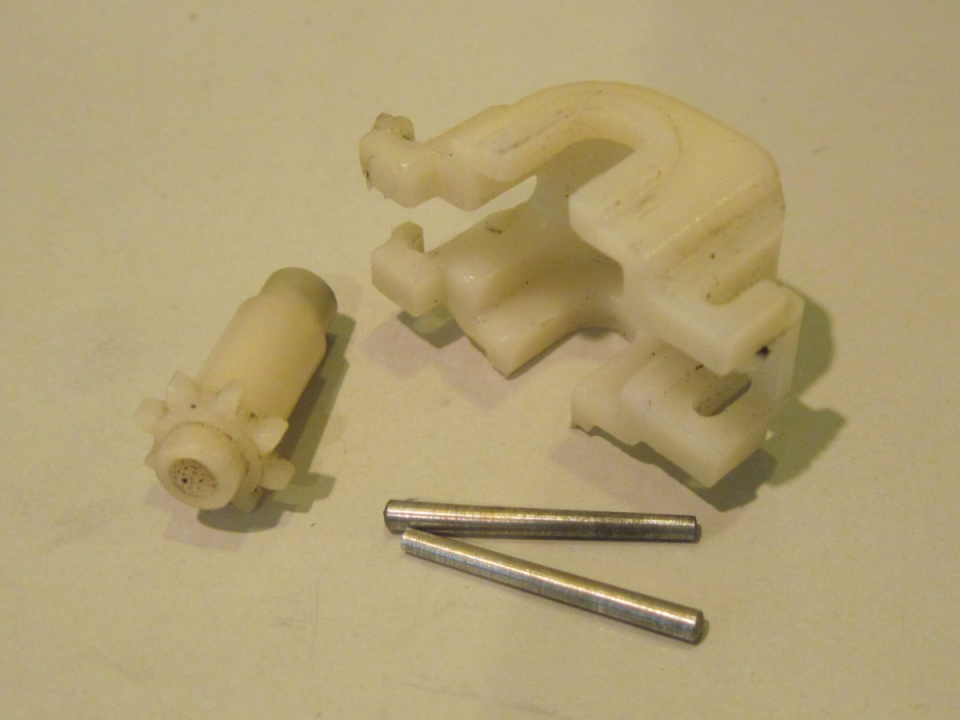

Then the trip odometer. There is a little gearbox that receives the odometer reset shaft. Smiths loved to use those little tapered pins to hold things.

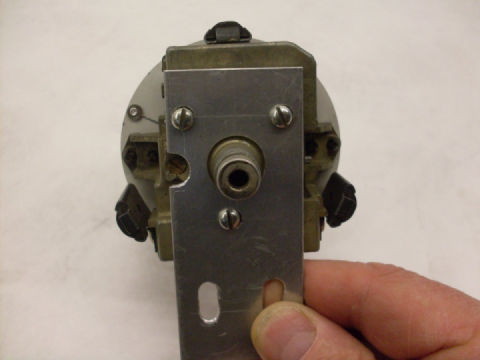

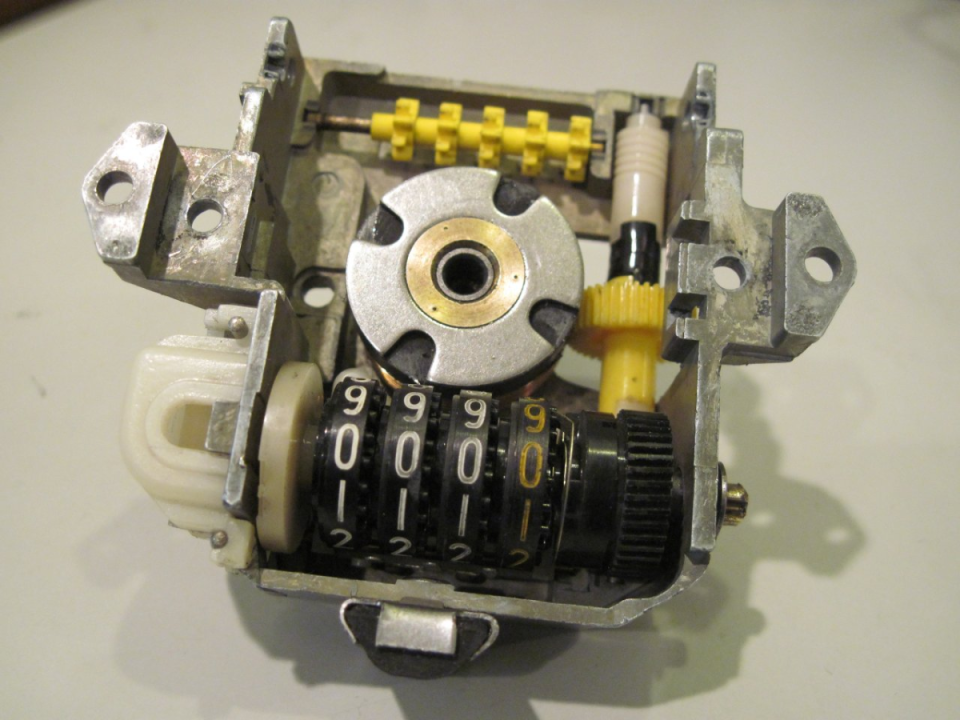

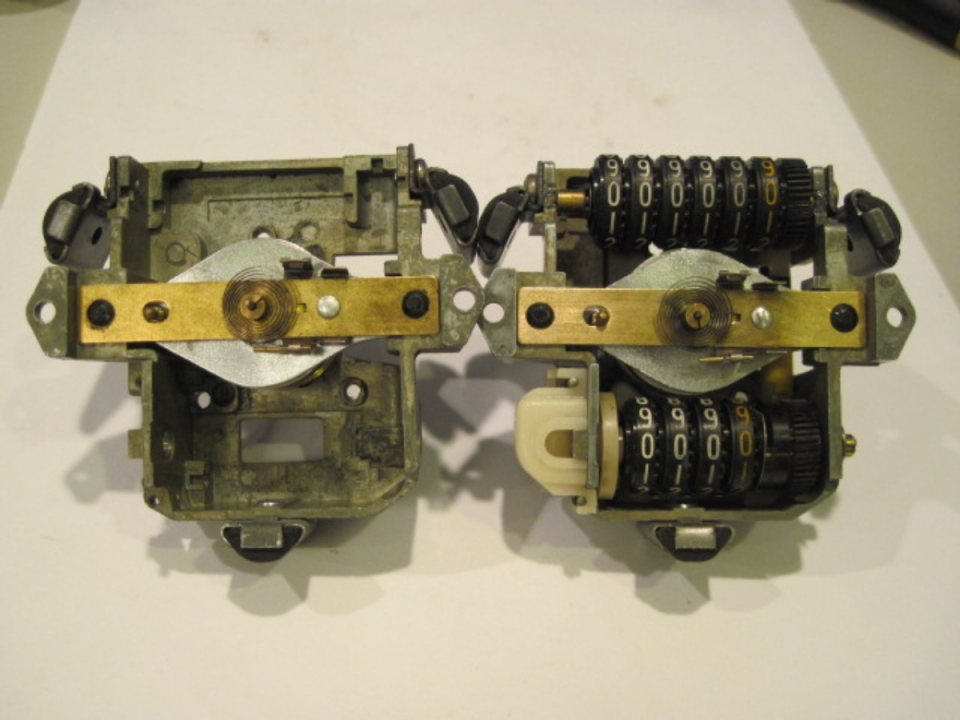

Here is the speedometer with the main odometer and the disc assembly mounted. The tach is simple by comparison

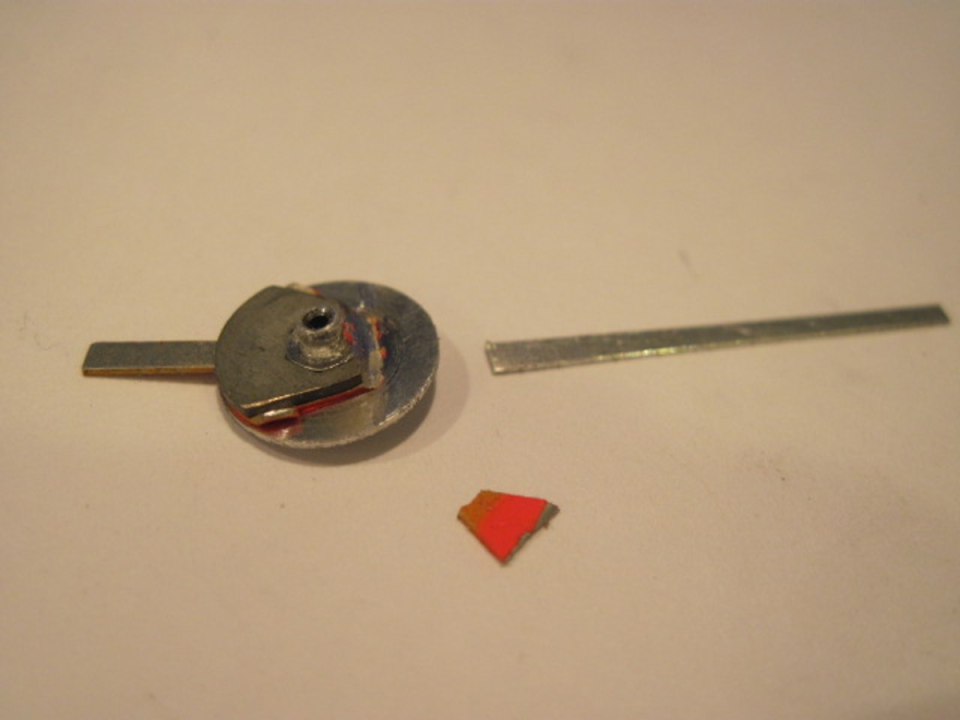

Then there was the matter of the broken pointer needle on the speedometer. Since it didn't look like I was going to find a junk unit, and I couldn't find anything suitable online, I had no choice but to try to dummy one up.

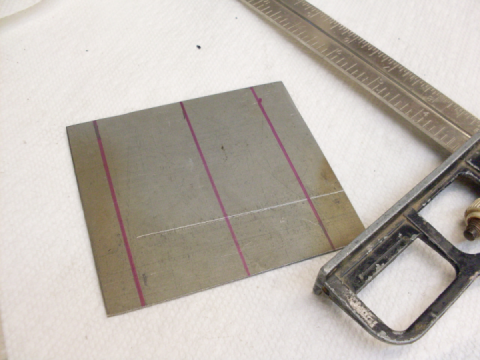

The pointers were made of aluminum, about 0.010 thick. I found some flashing tha fit the bill. I had to buy 10 square feet of it.

Cut away a little more of the old pointer under the hub, and fastened the new pointer with metal filled epoxy.

New fluorescent orange paint:

Follow

1.3K

Follow

1.3K