Instruments Pt. 6

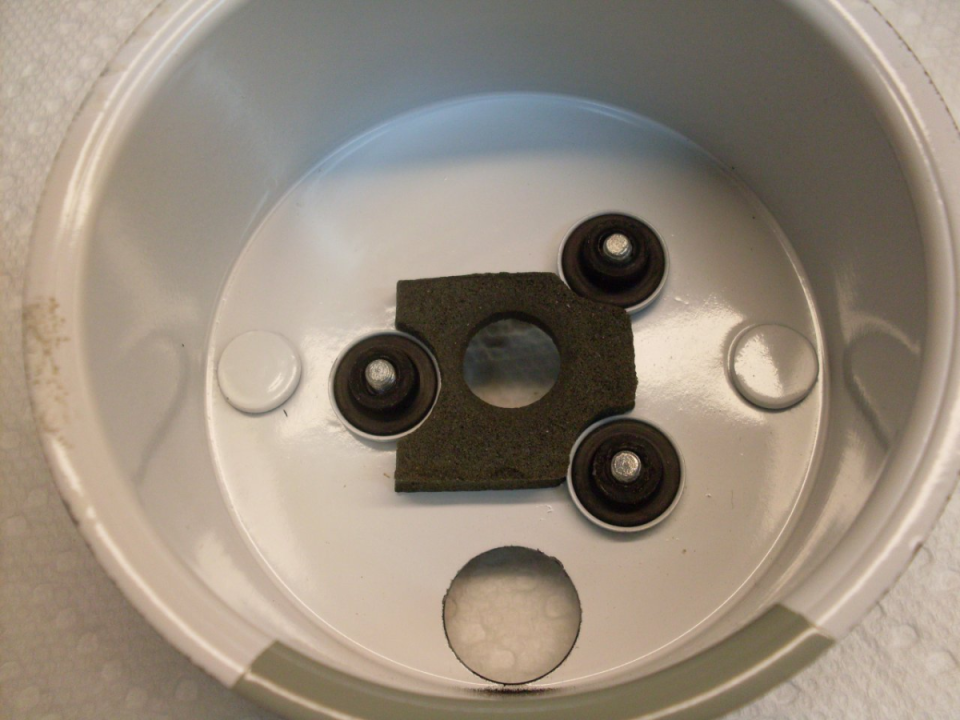

There is also a little foam cushion that goes in the bottom of the can.

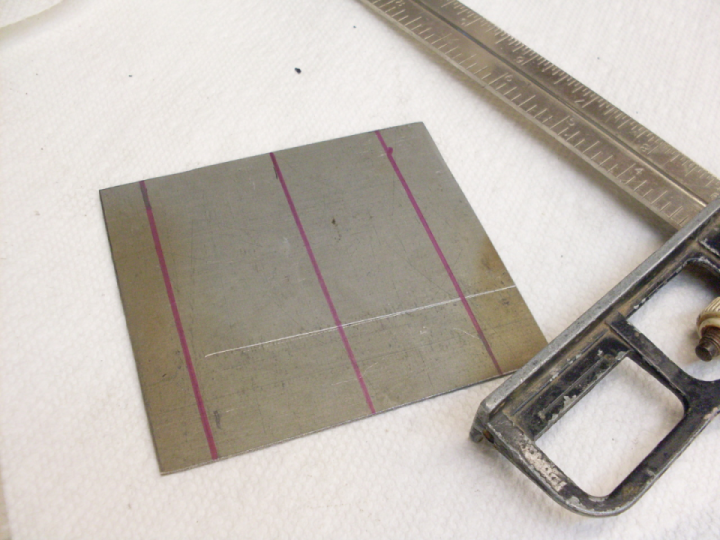

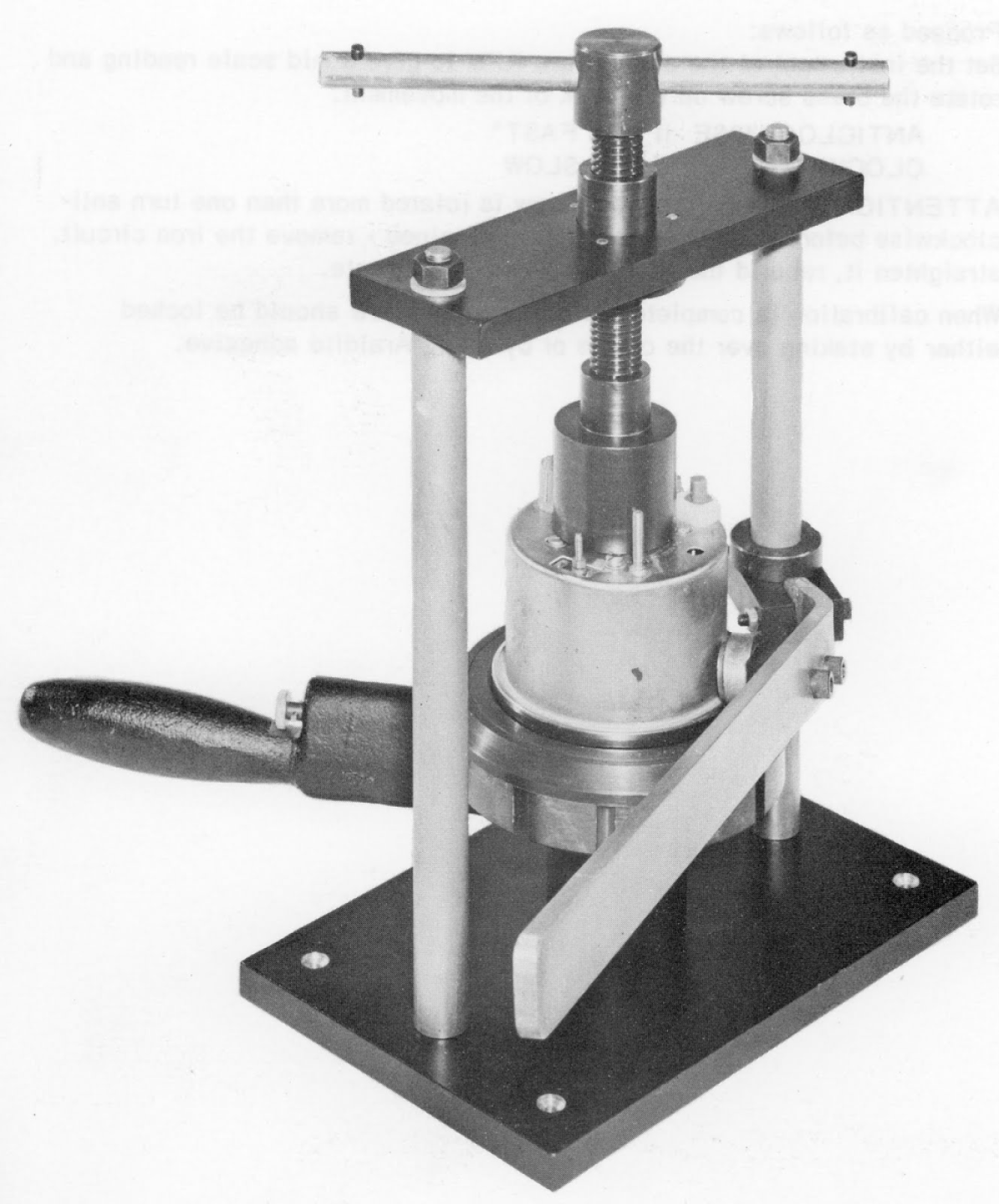

Made the trip odometer reset tool, since mine was long gone. Blighe's book shows a dimensioned drawing of the tool.

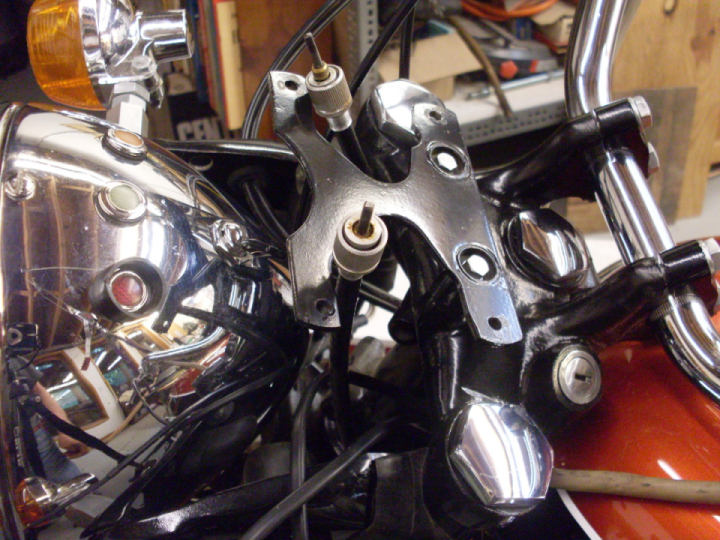

Ready for bezels:

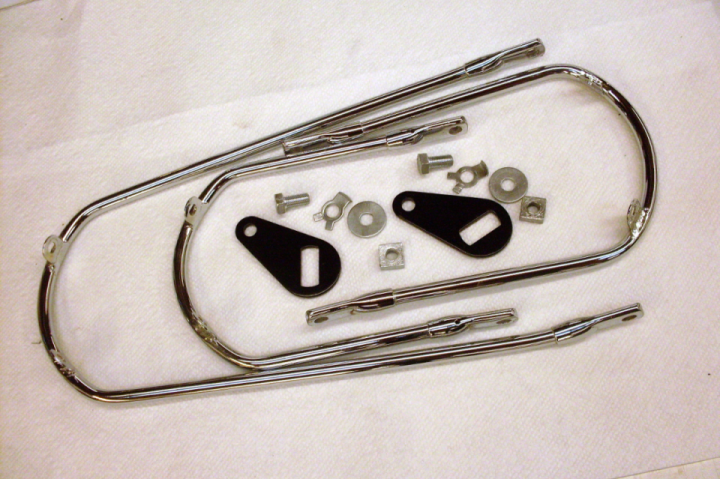

Bezel kits are available, and I ordered a couple. As anyone who fusses with old cars or bikes knows, reproduction parts are always a bit of a crap shoot. The first bezels I got for a good price were slightly too small, and would have required grinding a bit off the flanges of the instrument cases. I might have done that, but I also thought the quality of the rubber gaskets was shoddy. The next sets I got from a different supplier were much better. Even with the second pair of kits, one of them had a very visible scratch in the glass. My 40-year old original glass was better, so I re-used it.

The bezels must be crimped onto the instrument cases sufficiently tight to compress the rubber gaskets enough for a water seal. There are sources, including Blighe's book that suggest that the crimping can be done using simple hand tools. I was skeptical that a reliable seal could be guaranteed this way, so I did a little more research.

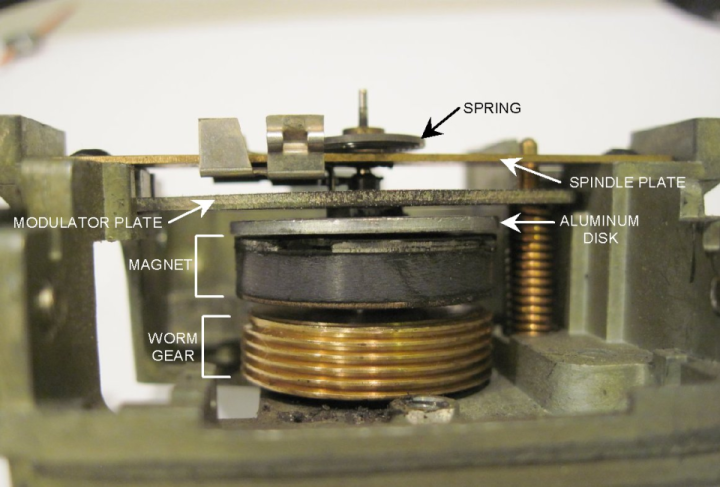

One very nice blog showed a picture of the "Smiths factory tool" for rolling the crimp:

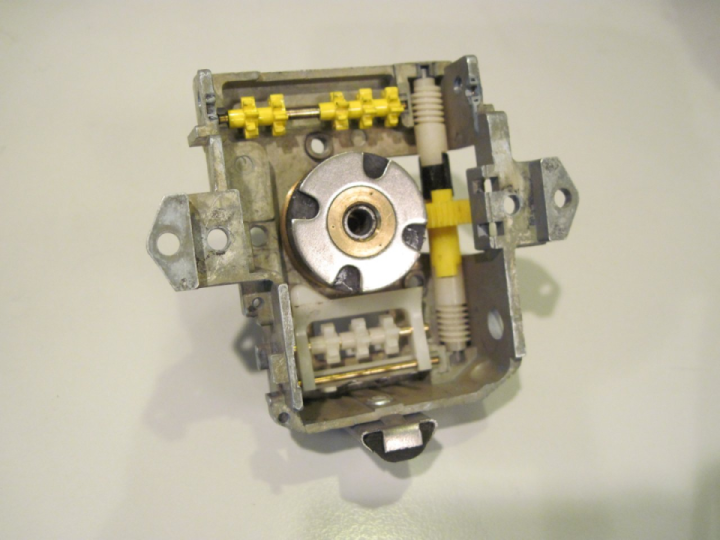

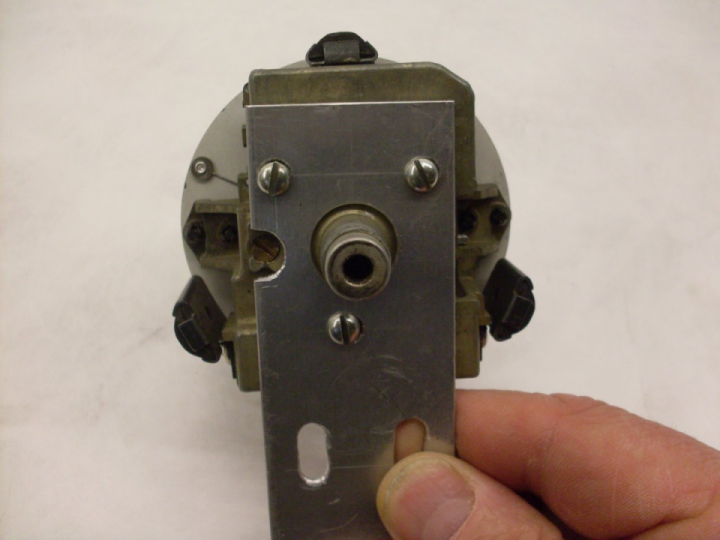

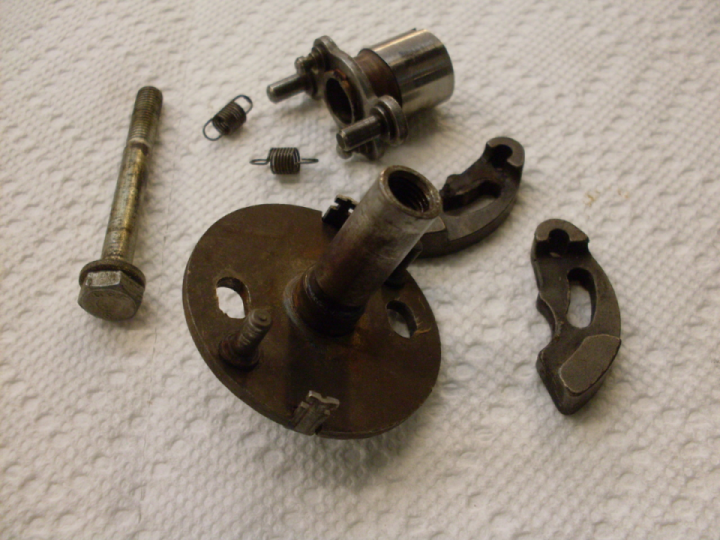

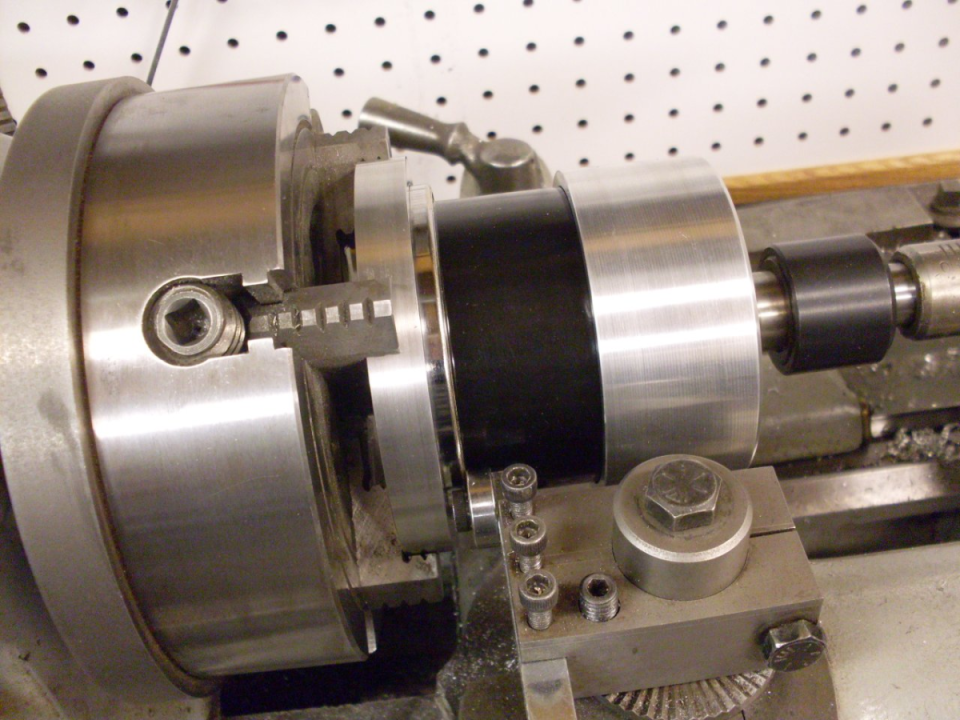

I considered building the tool, but the blog also describes a method using a lathe to press and turn the instrument while the crimp is rolled. I have a small lathe, so this seemed to be the better approach. First, simple adaptors must be made to fit the front and back of the instrument to hold it in the lathe.

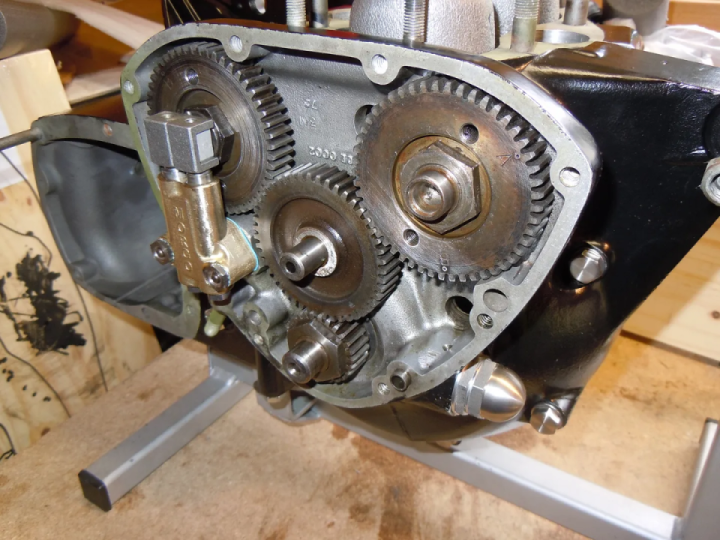

Also a ball bearing is fitted to a piece of key stock that is held by the lathe's tool post. The bearing is what rolls the crimp.

I didn't use power in the lathe--just turned the chuck by hand as the tool was slowly advanced. The crimping operation flakes some of the chrome plating off the brass bezel where the tool rubs on it. Not sure how to fix that, but it is pretty much out of sight anyway.

The finished speedometer. On the tachometer, which I did first, I put a thin smear of RTV on the gasket between the case and the glass to ensure water tightness. This was a bad idea, since the RTV made the gasket slippery enough to extrude out of place when the compression pressure was applied. Of course this couldn't be seen until the crimped instrument was taken out of the lathe. I had to remove the bezel, and order another one.

Follow

1.1K

Follow

1.1K