Tail Light Assembly

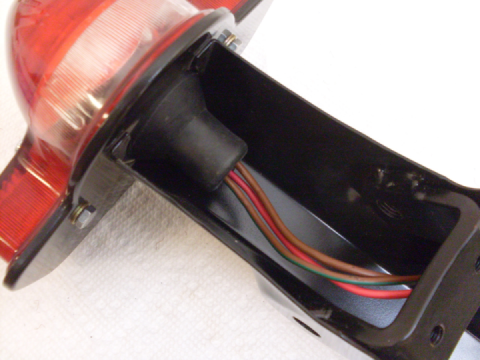

Here is the tail light assembly housing after I had already stripped and painted it. I think the original color might have been silver, but I like it black much better.

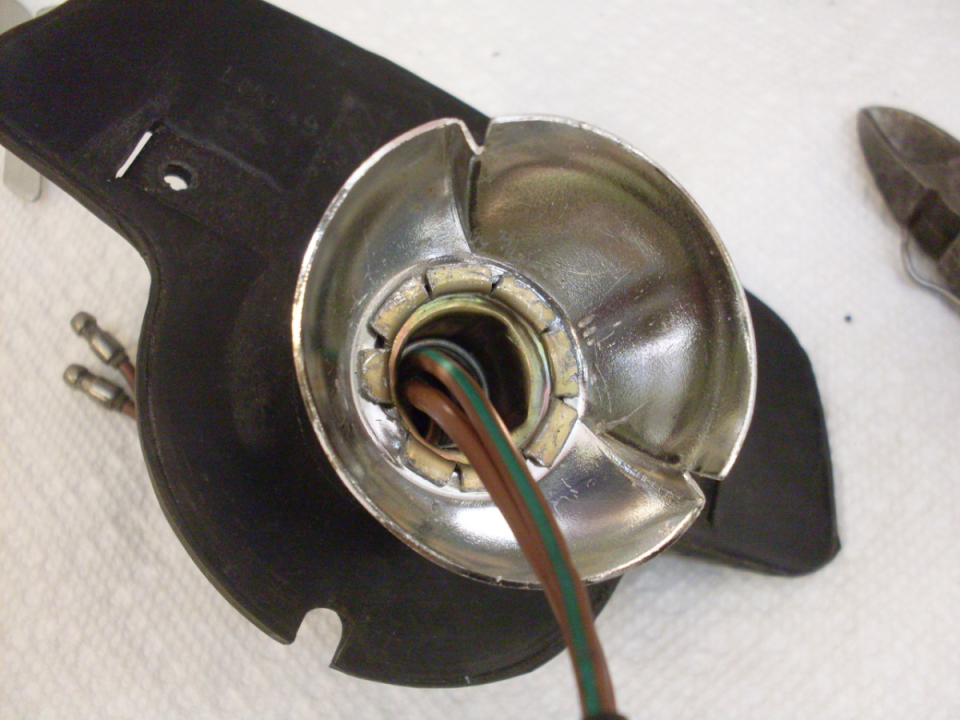

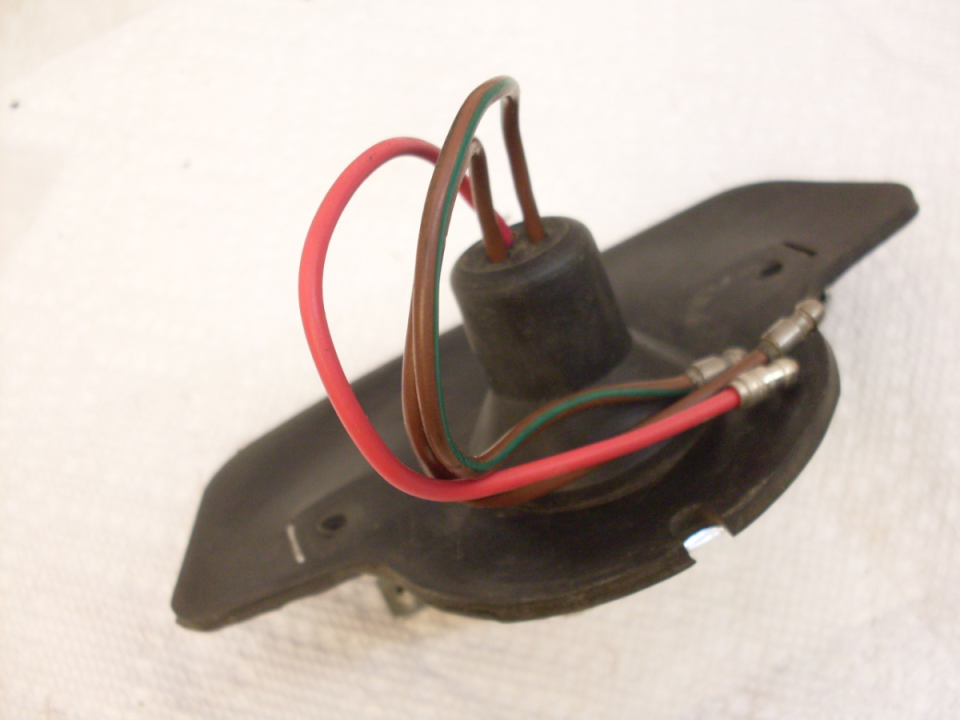

The components of the tail light. There is a bayonet socket for a dual filament bulb (tail and brake lights), which is held in a rubber boot/gasket. A thin aluminum reflector is crimped on the top of the socket.

A word about grounding on Triumphs. It was very common on older bikes (and cars) to use the metal parts of the frame and body as a return path for electrical circuits. These return paths often depended on fasteners to provide an electrical bridge from one frame or body component to another. Many times, these joints were painted and/or subject to corrosion, either of which could easily compromise the continuity of the electrical circuit, especially as the vehicle got older. The faults were notoriously hard to troubleshoot, since they could sometimes come and go with changes in temperature, moisture, or mechanical stress. Some time before this bike was born, Triumph had started including conductors in the wiring harnesses for these return paths, but in the case of the tail lights on this bike, the solution was incomplete. True, there is a return wire in the harness to the rear of the bike, but it just connects to the metal tail light housing. To get to the actual tail light bulb, the path goes from the housing to the bulb holder through two screws (equipped with external star washers to get through the paint), then on a short braided copper jumper wire to a copper ring crimped with the reflector on the top of the bulb socket. While this seemed to work OK when the bike was young, it could be troublesome later on. On this bike, there was some corrosion around the star washers, and the crimp on the bulb socket was very loose, causing the copper ring to flop around. I decided to finish the job that Triumph started, and put in real return wires.

After tightening up the crimp on the socket,I removed the little braided jumper and soldered a red wire to the tab on the copper ring. The wire runs down the side of the socket inside the boot, and comes out a new hole near the existing two wires.

I put everything back together, but replaced the star washers with small flat washers. It looks better, and the paint stays intact.

The last thing to do fot the tail light is see to the lens. It was dirty, dull, and scratched, but not cracked or broken. It responded pretty well to some light abrasives and some plastic polish.

Follow

1.6K

Follow

1.6K