Rocker Boxes - 2

Next, to the spindles. People who have bikes that leak from the spindles maybe wouldn't know, but since the spindles are steel, the exposed end will rust if there is no oil on it to protect it. Assuming I'll be successful in keeping the spindles oil free in this area, I decided to selectively zinc plate the ends of the spindles.

Many people don't know it, but the spindles (at least on some model-years) are not one piece..

For O rings, you can buy 100 for not much more than the four or five might go through before you're sure they're OK. You can experiment with different hardnesses, too. These are identical size, but one bag is 50 durometer (softer), and the other is 70 (harder). I don't know what was stock on a new bike, but I also don't have high confidence that the hardness you get from parts suppliers is necessarily what the factory used.

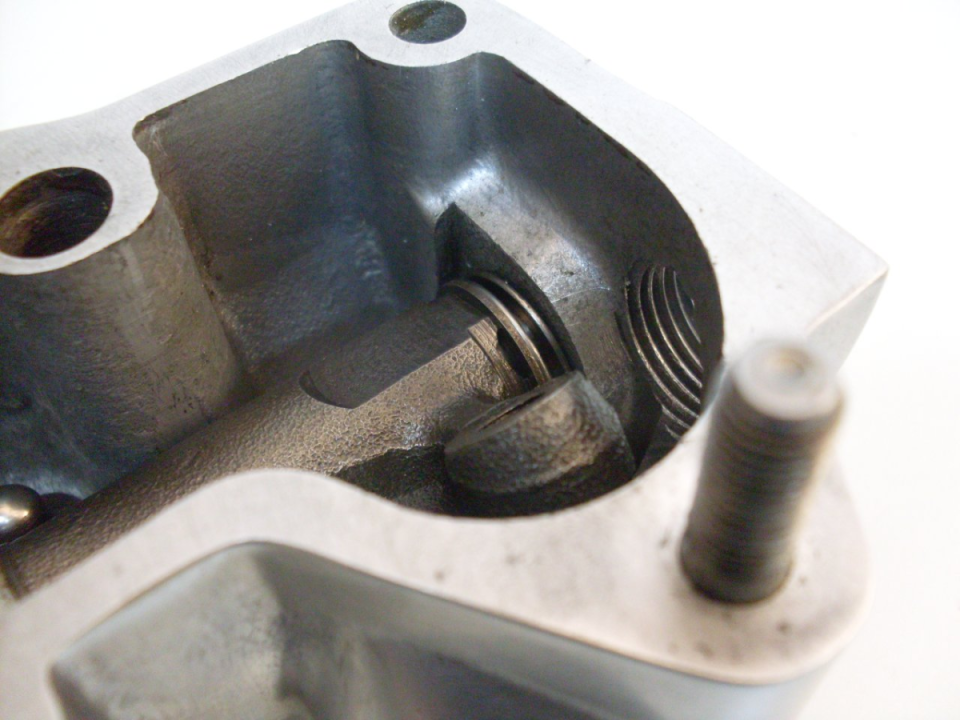

My rocker housings had been polished up pretty nice thirty years ago, and though they were grimy, they came back pretty easily. While everything is stripped, it's a good time to make sure all the oil galleries are clear and clean. like this one that feeds oil to the spindle.

One other area to watch out for, and it caught me at first, is that sometime in 1968, Triumph changed the way the ball ends of the rockers and the valve ends were lubricated, moving from drilled holes on the rockers to notches on the ends. This change necessitated a change in the way the rocker box was assembled. Specifically, the flat and spring ("Thackeray") washers shown on the outside ends of the two rockers in the picture below have to be assembled in the order shown for rockers with the end notch. Before this change, the flat washer on the threaded end of the spindle had a smaller ID than the others. After the change, all four flat washers were the same. As late as 1971 an possibly later, some parts and/or service manuals were still showing this incorrectly.

Assembly went well. I lubed up the chamfers, and the spindles went home nicely. It's best to press the spindles in rather than pull them in with the end acorn nut. That's how I found out that the spindles were not one piece.

Polished up the rocker adjusting pins, removing some worn areas:

All back together. A final buffing and they are ready to mount.

Follow

1.4K

Follow

1.4K