Fuel Tank Part 3

The only other oriface in the tank is for the fuel petcock. To eliminate as many external sources of leaks as possible, I decided not to use the petcock, but use a simple hose barb adaptor instead. This turned out to be a little more complicated than it appeared. What appears to be a 1/4" NPT pipe thread in the bung hole is not. The thread pitch is 19 instead of the NPT 18. There wasn't even a 19 TPI leaf in my pretty complete thread gage set (determined 19 TPI by using the 38 TPI gage). Turns out (seems obvious once you know) that it is British Standard Pipe (BSP) thead. Possibly if I lived in Europe, this would not have been a mystery at all.

I found a 1/4" BSP-to-1/4" NPT adaptor. Since it is a BSP straight (non-tatered) theread, there is a sealing washer included:

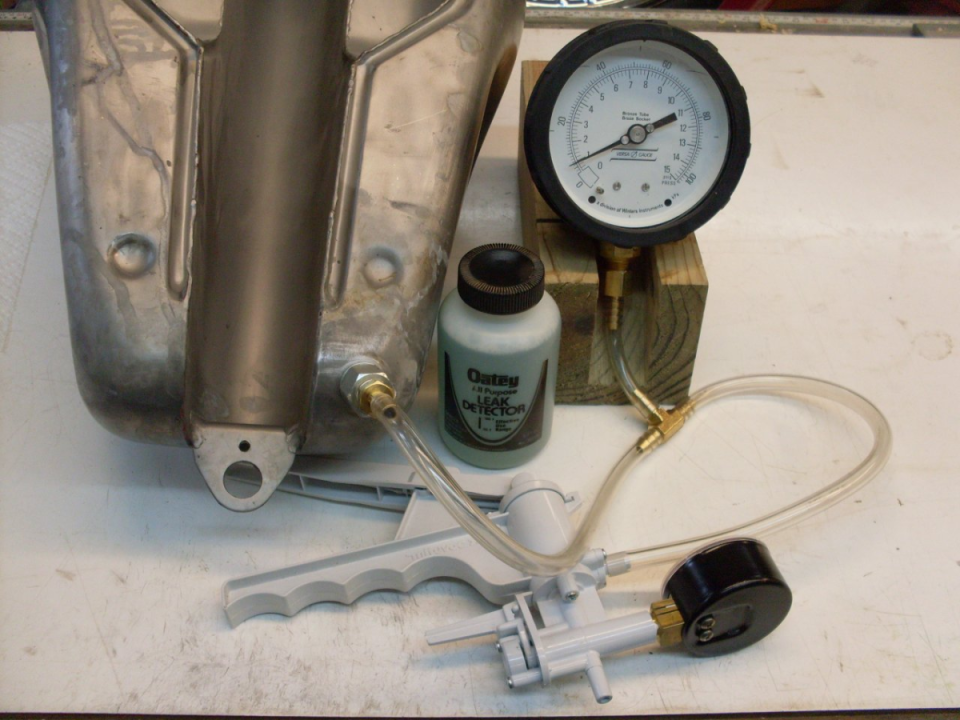

The pressurization setup consisted of a "MityVac" hand pump (normally used for vacuum, but there is a port on the pressure side), a pressure gage, and assorted tubing and fittings:

It doesn't take much pressure. In fact, it could be destructive or dangerous to use more than a few PSI in a tank not designed for it. I pumped up the system to 1 PSI. At this low reading, my gage is not very accurate, but I'm really only interested in whether the tank can hold pressure over time or not.

The pressure in the system decayed to virtually nothing over an hour or so, indicating a leak somewhere.

To find a leak, one common method is to dunk the pressureized assembly in a water tank and look for bubbles. I've done it this way before, and find it messy and cumbersome, especially if the gage and pump are still attached. I opted for what I think is an easier method.

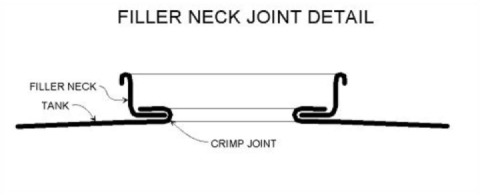

Using a solution made for the purpose (probably just soapy water), I swabbed all the joints in the tubing watching for bubbles, and found nothing. The bung hole and filler neck fittings appeared tight. Next I swabbed the detector solution along all the welds on the tank. The all appeared tight until...

Right where the rear mounting bracket was joined to the tank on its left side, there was an obvious leak.

Follow

1.5K

Follow

1.5K