Fuel Tank Part 4

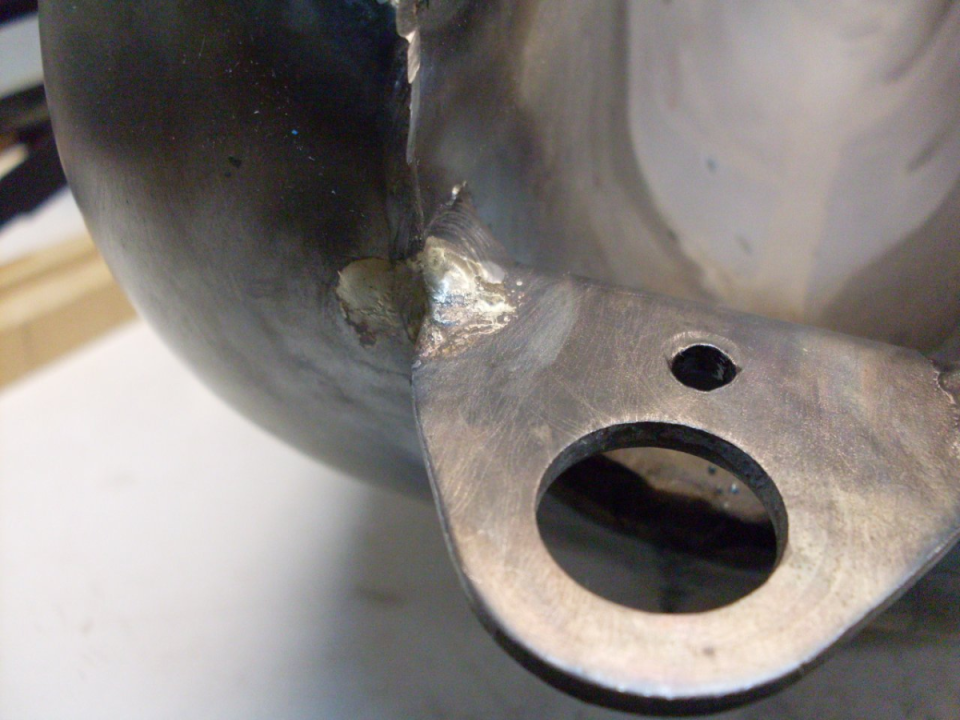

The leak was where the rear mounting tab was welded to the tank. It looked like an incompete weld, or a weld may have pulled loose or cracked. This would likely be a high stress area, and it's possible that the years of vibration eventually fatigued the joint. Looking back at the picture of the area around the petcock (fourth picture at top), it appears that the leaking was not all from the petcock. The crack was small--in fact when I started probing it with a sharp tool to clean it out, it stopped leaking. I probably shoved some metal or crud into the crack and sealed it. Nonetheless, I would have to fix it. Ignoring it would put any new paint at risk.

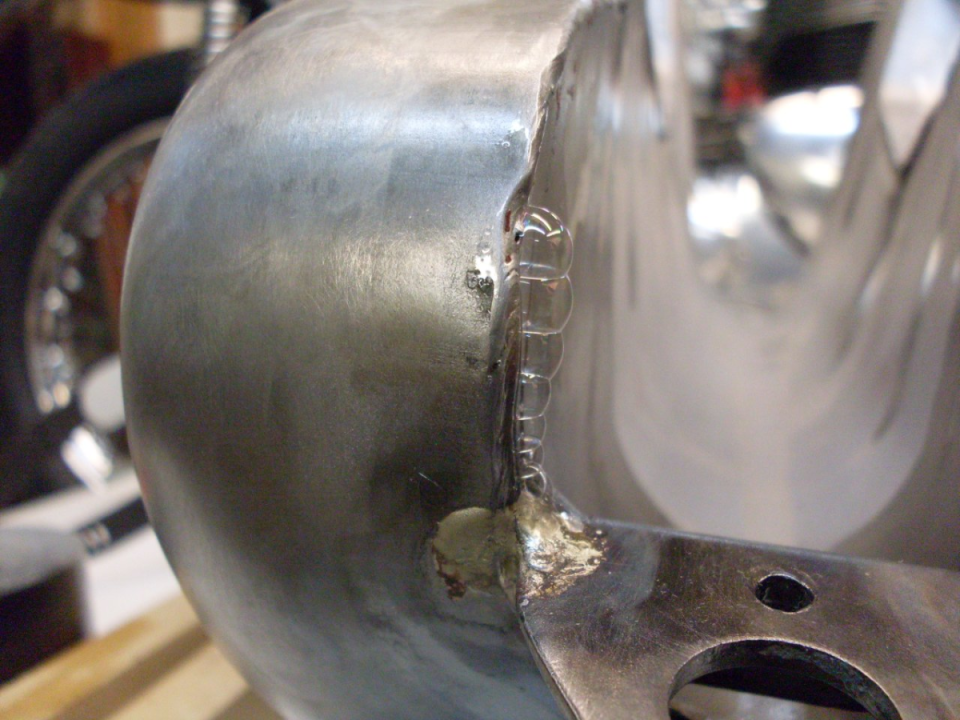

I decided to braze the area where the mounting tab meets the tank. I did both sides.

One more pressure leakdown test, and it looked like I still had a slow leak somewhere. Using the leak detector solution, I found it on the weld seam near the previous leak. I'm pretty sure this leak wasn't there before. Maybe the heat stress from the previous repair caused it.

After I fixed that, the tank held pressure for over eight hours with no detectable loss. Time for final prep for paint!

Follow

1.3K

Follow

1.3K