From its inception, our Kawasaki Vulcan 2000 project would include two stages. In the first, we'd take a competent motorcycle and make it bettermore what we would have wanted it to be from the factory. In the second, we would hand off our newly gussied-up cruiser to a customizer to show us all how real builders do things.

STAGE I

There's a funny thing about plans. While they always look carefully thought-out on the calendar, they rarely take into account the challenges encountered along the way. As any customizer (from the home-garage type to the grizzled pro) will tell you, the real story behind a custom bike is what happens while you're struggling to meet the demands of your schedule. Of course, trying to modify a relatively new-model bike for which aftermarket companies are still developing accessories will further complicate things.

Our list of absolutely necessary changes was short andwe thought—easily obtainable in the time we had. Weight loss was the major theme, with performance upgrades to complement the trim-down. While we like fat-look cruisers as much as anyone, we felt that, contrary to what the popular song may say, too much of everything may well be too much. So we began thinking fit and trim.

Off with Its Head(light)!

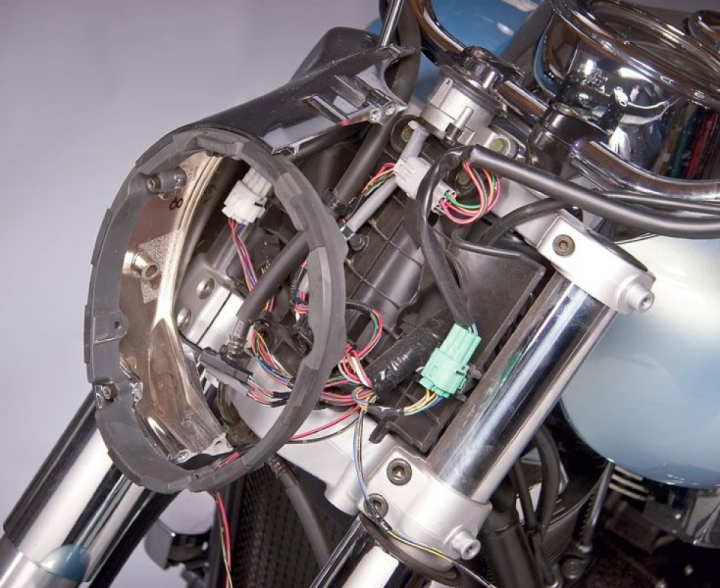

The first parts to come under our collective gaze were those associated with the headlight. Now, we're not saying the headlight isn't pretty. Still, we knew it set the tone for the Kawasaki Vulcan 2000's oversized nature we wanted to trim down. So after an hour or so of concerted wrenching, a mound of chrome sat on the garage floor and our V2K was 11 pounds lighter.

In the warm afterglow of a successful first step, we chose to ignore the challenges we'd just created for ourselves. First, our V2K no longer had a headlight and was, therefore, no longer street legal. Second, Kawasaki never intended for us to see the triple clamps, handlebar risers or the assorted wires and cables hidden under the headlight nacelle. Prior to this moment of understanding, we'd blithely thought we'd get the triple clamp chromed. Well, guess again, bucko. Quite simply, the triple clamp's casting was one of the ugliest things we'd ever seen. And rightfully so. Why would an OEM waste any money beautifying parts that were meant to be out of sight? So while we already knew we would be ordering a new headlight, a set of aftermarket triple clamps was added to the list. Only we couldn't find it anywhere. Apparently, we were a bit ahead of the curve, at the leading (or bleeding) edge on this little modification.

Pipe Down, Power Up

The next obvious place to remove excess poundage was the exhaust system. We looked around and found a svelte system in Cobra's catalog. The Speedster Shorts had the slim look we wanted, and the folks at Cobra said we'd be more than happy with the performance increase. Regular Motorcycle Cruiser readers are familiar with our aversion to overly loud pipes, so we were happy when the friendly Cobra representative said the pipes wouldn't offend our delicate sensibilities. A few days passed and a box arrived in our garage. The stock system, all 36 pounds of it, was already in the corner gathering dust. We immediately mounted the Cobra system. Now the V2K was another 16 pounds lighter and had an amazing exhaust note to boot.

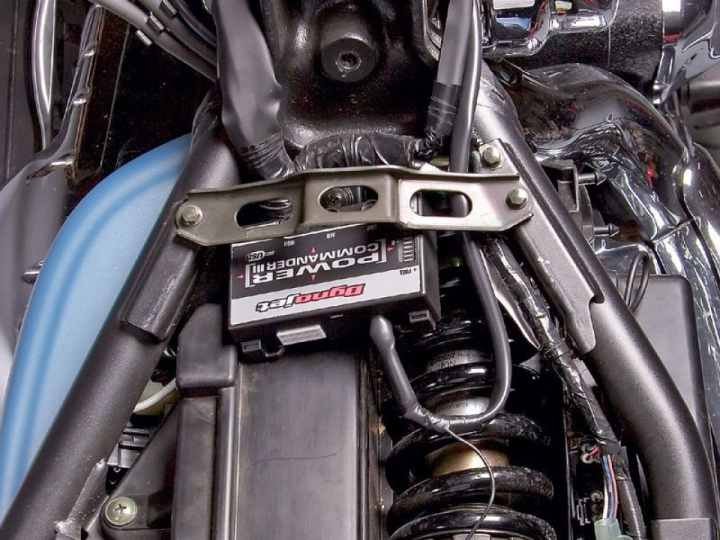

That same afternoon we also installed a Baron Custom Accessories Big Air Kit ($290) and a Dynojet Research Power Commander fuel-injection-adjustment unit ($332). As many experienced engine massagers have discovered, you can find bigger power gains by opening up a cruiser motorcycle's intake side than you get when you change the exhaust system. It also costs less and makes far less racket than the switch to a loud exhaust system. The Baron Custom Accessories Big Air Kit offered an impressive increase in breathing capacity and also looked much less bulky and provided a better view of the big Vulcan 2000 engine.

The Power Commander permitted us to adjust the Vulcan 2000's fuel injection to accommodate this improved intake flow. Dynojet's Power Commander simply plugs inline with the stock Kawasaki ECU with original-style connectors. This fuel-injection-adjustment unit smoothes out the bike's mixture through the rpm range in stock form. However, to optimize the ECU's maps for our set up, we took the bike to L & L Motorsports, one of hundreds of dealers trained and authorized by Dynojet to tweak the adustments of the Power Commander and the one that Dynojet recommended in our area. You can find one in your area at www.powercommander.com when you want to improve your bike's EFI.

When the airbox and extraneous hoses were removed and the new parts added on, the V2K was about a pound heavier. OK, as with any diet, we hit a momentary plateau. But we kept patting ourselves on the back because the bike was still 25 pounds lighter than stock, dropping the V2K below 800 pounds.

Held Up by Suspenders

While we were in diet mode, we also set out to improve some of the V2K's systems. First and most importantly, we addressed the rear suspension. We called two of our favorite suspension companies to see what they had. Works Performance said it hadn't had access to a Vulcan 2000 to develop a shock for it, and if we would be nice enough to loan the company ours for a week or two, it'd whip one up. Our call to Progressive Suspension revealed that, not only did it have a shock, it'd be happy to ship one out the next day. We called Works Performance to say thanks, but, you know, deadlines and all. Works was very pleasant about the whole thing.

Time passed. No shock arrived. A phone call revealed that parts of the shock were expected in the next day or so. After another couple of weeks passed, we contacted Progressive Suspension to find out where the shock was. The company was being held hostage by parts that still hadn't arrived and couldn't build the shock until it got them. So, faced with looming deadlines, we contacted Works Performance and asked...shuffle, shuffle...if it was still, uh, willing to develop a shock for us.

You'd think that after all these years in the motorcycle business we'd have acquired a taste for crow, but we still have to choke it down. Fortunately, Works Performance was more than willing. After leaving the V2K with the company for a couple of weeks, we had the first off-the-assembly-line shock for the V2K. (A brief aside: As this issue was going to press, the Progressive shock arrived on our doorstep, so its supply bottleneck has been resolved. Unfortunately, we weren't able to test it since the V2K was being packed away for the next stage.)

Fending for Ourselves?

While we were waiting on the shock, we had other side projects going. We were trying to find some stylish fiberglass fenders to replace the heavy steel ones gracing the V2K. Yes, we know metal is the be-all, end-all of cruisers, but we were on a weight-loss mission. The only problem was that we hadn't found a set of fiberglass fenders we could fall in love with. So we kept looking.

Right about this time we were contacted by Stephen Garrett Design about the collection of Vulcan 2000 parts being developed by the company. Two of them just happened to be fiberglass fenders and (hooray) billet triple clamps! The fenders give the big Vulcan a decidedly sporty look. The triple clamps are machined from solid billet and rake the front five degrees—enough to alter the bike's look without turning it into a chopper. As soon as we saw pictures of the triple clamps, we ordered a set without predrilled holes for a headlight mount. (We wanted to do this ourselves.) Unfortunately, the billet aluminum order for Stephen Garrett Design and its sister company, wheel manufacturer Cruise Concepts, was delayed, preventing delivery of the triple clamp in time for our deadline. Dang. We began looking for voodoo dolls around the office to explain this rash of out-of-everyone's-control delays.

On a more positive note, we ordered and installed a set of Goodridge&&& braided steel brake lines ($124 front and $69 rear). While the stock Kawasaki brakes were quite good, the new lines delivered even better feel at the lever, allowing remarkably quick stops from our still-beefy Vulcan. Readers should note, however, that the front lines took the more sportbike-like approach by bringing two lines up to the master cylinder rather than splitting them at the bottom of the triple clamp. While this makes bleeding the lines a breeze, cruisers who want a minimalist look at the master cylinder (particularly those who go to the trouble of running all the wiring through the handlebar) will want to custom-build their lines (Goodridge offers all the parts you need) to keep the clutter to a minimum. (See "Made to Order" in Motorcycle Cruiser's June 1998 issue.)

Progress Report

The results of our in-progress project are functionally impressiveif not yet visually so. The Works Performance shock dramatically improved the V2K's ride. By swapping out the approximately 960-pound stock spring for a 900-pound unit, the ride felt plusher without going soft. The developer said his philosophy was to soften the spring for smoother initial travel and use high-speed damping to prevent bottoming. Also, by better pairing the rebound damping with the compression, the Works shock doesn't kick back over harsh freeway bumps as the stocker did. The shock has an 18-position rebound damping adjuster to further help tune performance. (We found clicks six to eight from full stiff to be the best for our riding style.) The ride is still on the firm side, but this makes sense when you consider the suspension has to control just shy of 1000 pounds with a decent-sized rider aboard. The Works shock also has about 50 percent more oil capacity (thanks to its larger-diameter body) for fade-free bump absorption over rough pavement. The shock is available in stock length or 1.25 inches lower than stock (to allow for three inches of wheel travel) for approximately $589.

If we were impressed by the V2K's ride improvement, we were amazed by the power output of the combined Baron Big Air Kit, Cobra Speedster Shorts and Power Commander. Although peak horsepower isn't the most important part of this modification, these are the numbers people always look at first. In stock trim, the V2K put out 93.4 horsepower and 117.1 foot-pounds of torque. After having a custom fuel map created by L&L; Motorsports, the numbers jumped to 106.3 hp and 131.0 foot-pounds—a 12 percent and 11 percent increase respectively. While that might be nice, the numbers at partial throttle make the biggest impression from the saddle. At every throttle position above 2000 rpm, the modified fuel system makes more power. For example, at 40 percent throttle at 3000 rpm, the V2K makes almost eight more ponies. What this means out on the street is that simply rolling on the throttle gives you much better response than before. You don't need to run the engine out to the rev limit to benefit from the upgrades! However, when you do choose to wind out the engine, the combination of the intake honk, exhaust note and power increase is intoxicating.

These first chnages had made our Vulcan 2000 much more fun to ride. The suspension is what we wish it had been out of the box. The brakes offer much better feel for hauling the still-heavy machine down from speed. The engine itself is simply too much fun.

However, the V2K clearly needed a visual overhaul. Wires were hanging out in the breeze by the triple clamp, which is pretty darn ugly in its own right. It was time to pack this puppy up and ship it to a Texas fat farm for further weight reduction and a little cosmetic surgery.

STAGE II: MAJOR TRANSFORMATION

The expression is one we've seen from builders before—although we're usually seeing it as we're photographing a bike before it is rolled onto a trailer to go to a rally for its unveiling. This time, however, the debut is a little more private, as builder Stephen Garrett rolls the finished Vulcan 2000 Project (by now, simply "V2K" in our shorthand) out of his trailer. Garrett and his wife have just driven 1600 miles from Texas to Los Angeles, only stopping for occasional naps when they were both too tired to drive. Before that, Garrett had been up for the better part of three days making the final touches to the V2K. Garrett's eyes say it all: pride, exhaustion and a bit of nervous excitement at the prospect of showing the bike that had been the focus of countless phone calls and e-mails. As he backs the bike out of the trailer on this quiet suburban street, the evening sun wraps around the paint on the shapely bodywork.

Perhaps it was fate that had Garrett contact us while we were specifically seeking a new triple clamp to replace the stock one that was used to mount the headlight nacelle we had removed. As we talked to Garrett about parts for V2K, we realized that we had found our builder. In addition to the triple clamp we needed, he was also developing fiberglass fenders to fit Vulcan 2000s. All we had to do was get the bike from our garage in Los Angeles to his shop in Texas. In a matter of days, we said goodbye to our Kawasaki as it was loaded on a truck for its trip to Texas.

You Can't Be Too Thin

In our discussions with Garrett, he convinced us that, while our goals of lightening V2K were noble, we were ultimately fighting against the mass of the engine and chassis required to support it. We should embrace, rather than try to deny, the bike's big-boned nature and make it part of the look—only change the focus to that of a more muscular machine. To that end, Garrett convinced us that we should allow him to mount a massive, low-profile 250/40 R18 Avon Venom rear tire. This choice would have a slimming effect on V2K's profile. When viewed from the rear, there would be no question of the power put out by the two-liter twin. We were sold.

Garrett began the customization by modifying the swingarm to lower the ride height by almost four inches when coupled with the stock length Works Performance shock. Amazingly, he did not have to widen the swingarm to accept the 18 x 8.5-inch rear wheel. The 21 x 3.25-inch front wheel also did not require any modifications to the fork since the Cruise Concepts Cerberus wheel utilizes the stock brake discs and, consequently, the stock caliper mounting points. The Five Armed Cerberus wheels are the first pattern billet wheels Cruise Concepts has released for the VN2000 and are currently shipping to customers. The rear wheel is particularly dramatic since, on the big Vulcan's rear pulley, there is no oversized hub required to accommodate a shaft drive. While these changes rendered the stock fenders obsolete, we always planned to jettison them for lighter, fiberglass ones. The frame rails did not have to be altered to accept the 250 series rear tire. (Kinda makes you wonder if Kawasaki built the 2000 to be customized, doesn't it.)

On the front of the bike, a few modifications had to be made before the Garrett Design triple clamp could be fit to the bike. First, all of the crud associated with the fork covers had to be removed. Next, to tie the new front end together, the fork sliders were polished to match the shiny billet triple clamp. The other components to hit the buffing wheel were the calipers and the stock discs. Cleaning and polishing these parts added to the visual appeal while allowing the money saved to be used on other parts of the bike. While some people might go as far as chroming these components, we think that mixing different kinds of metal and chrome gives a more eclectic feel to a cruiser than simply dipping all the shiny parts in chrome.

Color Me Orange (with a bit of Kawasaki Green)

While these modifications were under way, the topic of much thought and discussion surrounded the color scheme of V2K. The original plan was to paint just the bodywork and leave the frame dressed in its factory black clothing. Well, PPG and Tyler Paint and Body Supply stepped in with a new paint named "Oh So Orange." Once we'd seen how radically the paint flip-flopped from brilliant pearl orange to pearl emerald green with the change in light, we were hooked. The decision was made to coat the bodywork and frame in this paint—without graphics. Our reasoning for following this path was we've built bikes with completely over-the-top graphics and more subtle ones (see our April and December 1997 issues) and thought it would be nice to try something dressed in one color alongside the shiny stuff. Oh, and then there's the little thing that the builder (whose opinion we were beginning to trust implicitly) wanted to do it this way.

Before the paint could be applied, however, the bodywork had to be built. Garrett's previous company built aftermarket fiberglass parts for trucks, so he's familiar with the process. He begins by building big, funky looking plugs, which are basically 50-pound fenders constructed of wood, fiberglass and Bondo. Then the fenders are shaped, reshaped, slathered with more Bondo and reshaped again. Garrett claims he used about nine gallons of Bondo before he'd arrived at the shape of the two fenders. The next step is sanding and prepping the fender just like you would for painting—even applying gelcoat primer. Once this is done, a reverse fiberglass mold is created from the fender. The upshot of all Garrett's hard work is that he will be able to reproduce these fenders for other customers. The challenge for V2K's rear fender was to make it low enough to maintain the clean lines Garrett desired while still allowing the rear suspension to travel through its range of motion. Once this was achieved, he played with the shape of the fender's trailing edge until he was satisfied. The job of wrapping the sleek front fender around the 21-inch wheel and tire was less complicated (since it didn't have to accommodate suspension travel) but no less detail oriented.

Most but not all of V2K's bodywork was altered. Garrett left the tank unchanged with the exception of paint color. He felt that the tank was just about the perfect shape from the factory. The frame received a little more attention prior to painting. Welds were smoothed, holes were filled, and unnecessary tabs were cut off to make the stock chassis as pretty as it could be. Once the decision to change the frame from black to orange was made, Garrett knew he had to get the black wrinkle paint off the engine. Hours of sanding ensued, and even that doesn't do justice to the labor involved in getting the wrinkle paint off the engine. However, when you see the 2005 Lamborghini Murcielago Titanium paint gracing the engine next to the orange of the frame (both applied by M.A.B. Grafix), it's pretty obvious that the effort was worth it. The color of the paint also gives the impression that extra portions of the engine were polished, but Garrett claims it's completely stock. Only a Baron's Big Air Kit and a billet timing cover grace the engine with their shine. The Cobra Speedster Shorts installed in the performance portion of the project also add to the engine's good looks.

Final Details

As with most custom projects, once the major chassis and rolling gear modifications are complete, the most challenging part of the building begins—deciding what components to accessorize the new bike with. Garrett took a measured approach with V2K. Rather than swapping every possible part with a chrome replacement from the aftermarket, he left a smattering of OE parts installed. For example, the instrument cluster's bezel and the fender rails are both standard equipment. Sure, he could have changed them, but they looked good with the bike's new lines, so why do it just for the sake of doing it? Instead, he focused on making measured changes to portions of the bike. The handlebar is an L.A. Choppers Z-Bar coupled to a set of Harley-based Arlen Ness switch gear/hand controls and grips. An Aeromach Extreme Oval Mirror mounted to a Slayer provide a stylish but minimalist rear view. A pair of custom-length Barnett cables transmit the rider's input to the engine. (A short note about mixing Harley and metric controls: The ends on the cables are often different, so you have to specify which fittings should be mounted to which end of custom cables.) The finishing touch for the front end was an Adjure seven-inch smooth headlight (which like the Ness grips, came from ) coupled with a set of Lazer Star LED turn signal/running lights from JP Cycles.

One of the coolest touches of Garrett's triple clamp is how he (in one of those crazy ideas you get when building a bike) decided to turn the bottom triple clamp into a brake distribution block. In other words, one Goodridge line runs from the master cylinder, through the upper triple clamp, and screws into the top of the lower triple clamp. The stainless lines for each of the calipers then screw into the bottom of the lower triple clamp. How'd he do that? He drilled holes from the back of the lower triple clamp to create the distribution block's pathways. These holes were then plugged. The three mounting points for the brake line fittings were drilled into these pathways, then tapped. Just pause for a second and think about the careful planning that has to go into this stunt: There are already several bolt-holes in the lower clampincluding the press fitting for the steering stem. A bunch of variables could have turned this into an expensive-but-pretty paperweight.

The transformation is complete. We may not have attained all the lofty goals we hoped for when we first decided to do this a year before. Any firther weight loss would require a special frame, for example. But our final product is lighter, rides better, and definitely has a more streetwise character.

RESOURCES:

- Builder: Stephen Garrett Design

- Rear shock unit by Works Performance

- Five Armed Cerberus wheels by Cruise Concepts

- Venom tires by Avon Tyres

- Speedster Shorts exhaust by Cobra Engineering

- Power Commander by Dynojet Research

- Big Air Kit by Baron Custom Accessories

- Power Commander tuning by L&L; Motorsports

- Clutch and throttle Cables by Barnett Tool & Engineering

- Brake hoses by Goodridge

- Seat by Qualitex

- Yaffee Long Barrel Risers * Yaffee throttle sssembly * Ness Tech hand controls and switches * Thunder Heart forward foot controls * Thunder Heart passenger pegs * Adjure 7-inch Smooth Headlight * Adjure headlight bulb * Custom Chrome license plate frame/brake light by Custom Chrome

- Lazer Star turn signals, amber/red * Turn Signal flasher/load equalizer by JP Cycles

- Mirrors and stalks by Aeromach Manufacturing

- Z Bars by LA Choppers

- Cam cover by Baron Custom Accessories

- Painter by M.A.B. Grafix

- Paint by PPG/Tyler Paint & Body Supply

For more articles on how to customize and modify your motorcycle, see the Custom section& of MotorcycleCruiser.com.

#Kawasaki #Vulcan #Moto #Bike #Chopper

#Kawasaki #Vulcan #Moto #Bike #Chopper