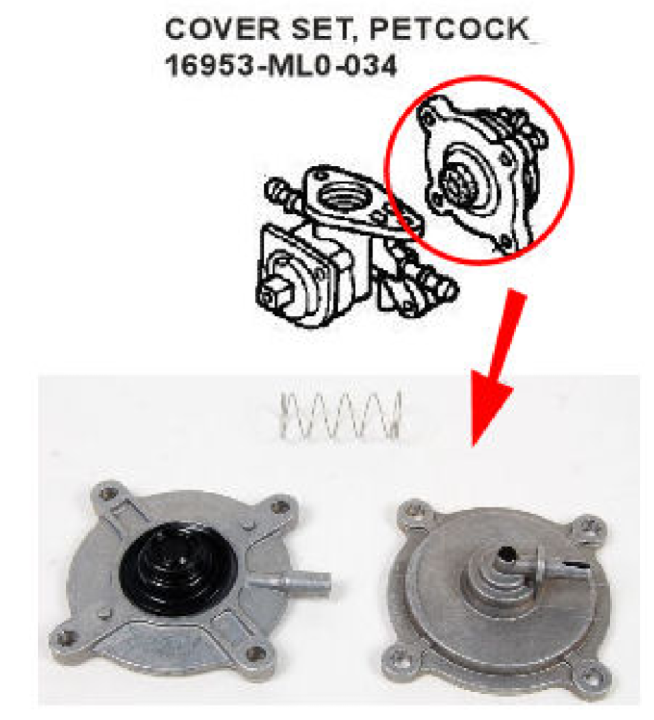

Fuel Petcock

This bike had an Ewarts dual push-pull petcock that combined the main and reserve valves into a single unit. It had been leaking badly when I last rode it 30 years ago, and I'm sure whatever fuel was in it when I parked it was soon gone.

The Ewarts, at least of this era, used cork gland seals. Though some report that they have rejuvenated cork seals even this old by various processes, including boiling or soaking in various fluids, I really believe these were toast. They were shrunken, dessicated, and brittle.

I've seen upgrade kits that involve drillng out the brass center part of the valves, and replacing it with a new brass part with two O ring grooves machined in. This was an attractive approach, but the kits I saw were over $30 each--and I'd need two of them. Still, the O rings seemed to be in the right direction. I ordered some O rings of the approximate size to fit the bore of the valve housing. In playing with them, I found that a -105 O ring was a good fit on the plunger spindle, but very loose in the bore. The next size larger, a -106 was a good fit in the bore, but loose on the spindle.

My final solution was to use two of each size, with the smaller ones between the two large ones. The dimensions of the spindle were just about perfect for this arrangement. These rings are of Viton material, which has higher resistance to chemical exposure than some other choices.

I smoothed out the bore of the valve body to make sure the O rings would slide smoothly, but the action was still pretty stiff. I found some fuel-resistant grease that made the feel just right--firm, but smooth.

The final rebuilt petcock. There's just a dab od Medium Locktite on the keeper screws to keep them from wandering off. Can't wait until the day I can mate this dude to the tank.

Follow

1.6K

Follow

1.6K