Seat. Part 2

The seatcovers on these seats are stretched around the foam and then over the lip on the pan. While it's been done this way for decades without serious problems, that lip seemed awfully sharp to me, and I was a little afraid that the very high tension necessary to stretch the cover could cause the lip to cut the cover. I think the rust had thinned the lip of my pan in places so that it was even sharper than usual. To put my mind to rest, I put several layers of vinyl tape around the lip just ot give a little radius and cusion to the edge. Probably not necessary, but it made me feel better.

Now for the seatcover. As I said, I'd seen a few videos on putting on seatcovers, but by far the best guide I found was an article by John Healy at Vintage Bike Magazine. Without this, I'm sure I would have convinced nyself that I had the wrong seatcover. The seatcover has to both compress the foam and also stretch quite a bit. At first, it looks like the cover will never go on. Following John's instructions, it wasn't too bad. Where John uses clothes pins, I used binder clips borrowed from my employer's office suppy closet. [note to self: be sure and get the 62 clips back to the closet by monday am.]

The cover has to be warm to stretch. Some people do it out in the sun. I used a couple of 500 watt work lights. It only takes a few minutes, and these lights could probably melt the vinyl if left too close for too long.

Almost there. Have to make sure the Triumph logo ends up centered.

When the cover is in final place, the chrome colored plastic finishing strip gets pushed over the lip of the pan. Some of the videos I saw implied that the strip is all that is necessary to hold the cover in place. However, my pan had a series of barbs punched out of the lip that pierce the cover. When I removed the old cover, I very carefully bent the barbs up, stressing them as little as possible. The barbs can't be bent too many times before they break off. I pulled the cover down over the barbs until they broke through, then carefully bent them back down enough so not to be dangerous. A couple of them broke off in the process.

The strip is stiff and won't easily go over the lip unless it is heated. I used a heat gun for this, but a hair dryer would have been better. A couple of times I got the strip a little too hot and it buckled rather than slipping ove rhte pan lip. It's noticable to me, so I've ordered another finishing strip.

So the cover is on, and doesn't look too bad. There are a couple of places where I can see where the cover was folded for shipping, but I understand these will come out over time, or with the help of a little gentle heat.

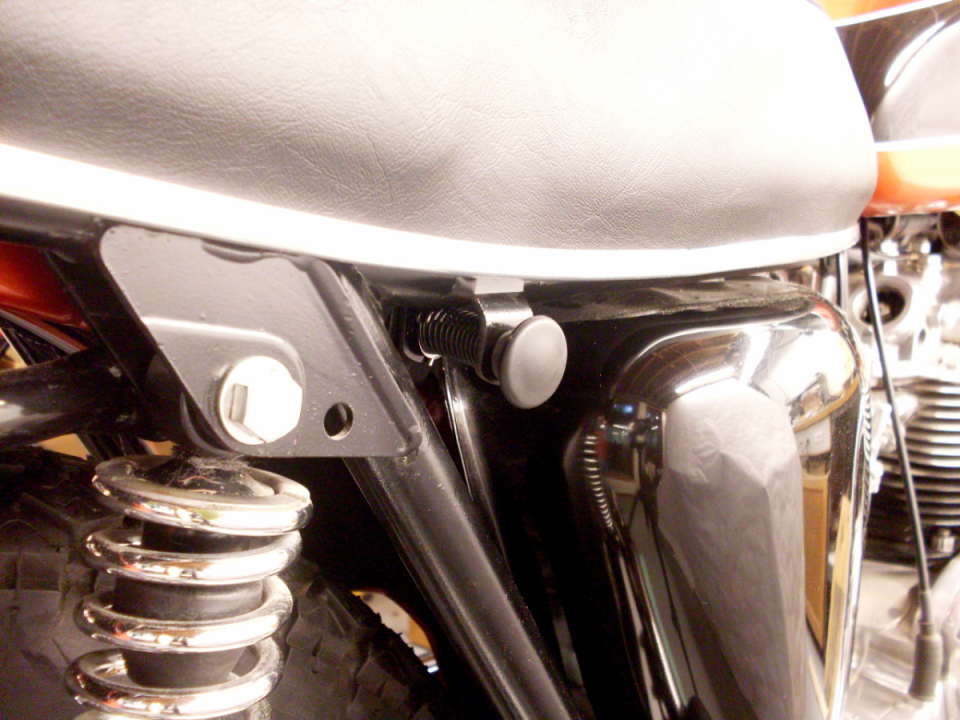

There are four rubber bumbers that compress against the frame when the seat is down and latched. Ideally these should have been put in before the the cover was installed, but it wasn't a big deal. I had a heckofatime with the rear bumpers until I realized that the holes in my pan were 3/8" while the bumpers needed 1/2". An electrician's reamer and a littl P80 took care of that.

The hinges, latch mechanism, and the stay cable, and the seat is done.

Now I have a new place to sit!

Follow

325

Follow

325